How 3D ToF Cameras Are Driving Transformative Progress in Smart Agriculture?

Let’s explore a fresh and inspiring case of how cutting-edge 3D vision technology is revolutionizing agriculture.

In Nanning, Guangxi—known as the “Jasmine Capital of China”—about 80% of the nation’s jasmine flowers are produced. This “Oriental Rose,” with its delicate fragrance, has become a golden symbol of the city’s prosperity and charm.

The jasmine blossom season peaks in August, right in the heat of the Guangxi summer. Under the blazing sun, pickers work tirelessly in the open fields without shade, facing extreme heat and fatigue.

To address this challenge, a top domestic university research team, leveraging Goermicro’s 3D ToF camera DS series, successfully developed an automated jasmine harvesting system. The feasibility trials have been completed with excellent results, and mass production is now on the horizon.

Table of Contents

Strong Demand for Automated Harvesting

Using 3D vision, the system precisely identifies each flower’s position and blooming stage. A robotic arm can then complete the full process—lock-on, extend, pick, and collect—within seconds. Field tests show:

- Identification accuracy exceeding 98%

- Picking success rate above 90%

- Stable performance even under morning dew or low-light evening conditions

This project not only demonstrates the powerful perception capabilities of 3D ToF cameras in complex agricultural environments but also marks a technological milestone—the first large-scale automation of jasmine harvesting in China.

The Demand for Automation in Smart Agriculture

With global agricultural labor shortages and growing expectations for consistent crop quality, “on-demand harvesting” and “in-field grading” have become essential directions for modern agriculture.

However, traditional manual harvesting faces several pain points:

- Low efficiency and high cost – heavily reliant on manual labor

- Limited precision – difficult to assess bloom maturity accurately

- Inconsistent quality – manual handling can easily damage delicate flowers

Automated harvesting systems directly address these issues. They not only enhance yield and uniformity but also, through integrated vision-based grading, can identify and pick only the best blooms—achieving “harvest as premium.”

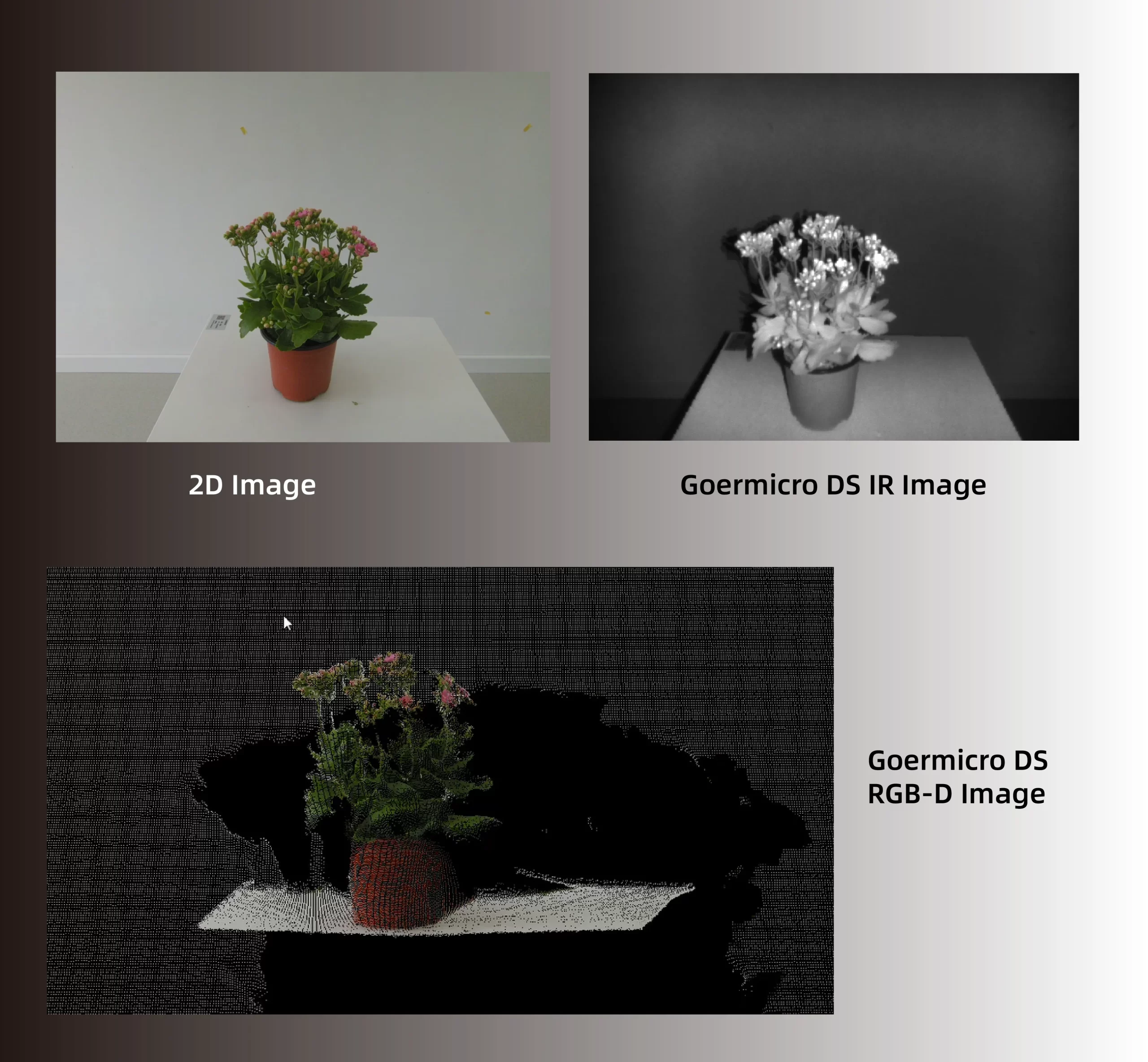

The Limitations of 2D Vision and the Breakthrough of 3D ToF Cameras

Earlier automation efforts often relied on 2D cameras for flower recognition. However, 2D vision has inherent limitations:

- Highly sensitive to lighting; shadows and reflections interfere with detection

- Lacks depth information, making it impossible to accurately determine flower height

- Poor performance under occlusion—jasmine flowers are often hidden by leaves

3D ToF (Time-of-Flight) technology provides a revolutionary solution to these challenges.

By emitting near-infrared light pulses and measuring their travel time, a ToF camera generates a full depth map, precisely locating each flower in 3D space (X, Y, Z).

This allows the system to:

- Accurately identify each flower’s position, size, and blooming level

- Plan robotic arm trajectories intelligently

- Control picking force delicately to prevent petal damage

The robustness of 3D ToF cameras ensures reliable operation even in bright sunlight, shadowed areas, or moist environments such as early mornings.

Comparison: 3D ToF vs. Other 3D Vision Technologies

To better understand how different 3D vision technologies perform in agricultural settings, here’s a comparison among Stereo Vision, Structured Light, and Time-of-Flight solutions:

| Comparison Dimension | Stereo Vision | Structured Light | Time-of-Flight (ToF) |

|---|---|---|---|

| Depth Accuracy | Medium; depends on texture | High; suitable for static measurement | High and stable; ideal for dynamic scenes |

| Environmental Adaptability | Weak; strongly affected by lighting | Moderate; limited under strong light | Strong; minimally affected by ambient light |

| Real-Time Performance | Moderate; heavy computation | Fast; limited by projection refresh rate | Very fast; millisecond-level response |

| System Complexity | High; requires strict calibration | Medium; needs synchronized projector and camera | Low; single-camera structure, easy to integrate |

| Typical Applications | Indoor labs, controlled settings | Industrial inspection, fixed targets | Agricultural harvesting, logistics recognition, autonomous driving |

Conclusion and Outlook

The integration of 3D ToF vision with intelligent robotics is emerging as a key technological breakthrough for smart agriculture.

High-value crops such as jasmine are transitioning from “manual experience-based harvesting” to “machine vision-guided harvesting.”

Future directions include:

- Multimodal sensing fusion (ToF + RGB + Hyperspectral) for enhanced recognition robustness

- Lightweight, low-power platforms optimized for field deployment

- AI self-learning models that dynamically adjust harvesting strategies based on bloom stage and lighting conditions

As both algorithms and hardware continue to evolve, 3D ToF technology is poised to become the crucial perception bridge between nature and machines, injecting fresh technological momentum into China’s smart agriculture—and its global competitiveness.