In the agricultural sector, technology is improving the way we cultivate, monitor, and harvest crops. One of the most exciting advancements is the application of Time-of-Flight (ToF) cameras.

According to a recent study on ToF technology , Time-of-Flight cameras are transforming smart agriculture by providing high accuracy and efficiency, especially in automated harvesting.

Table of Contents

The Role of Time-of-Flight (ToF) Cameras in Smart Agriculture

Precision is critical in crop harvesting. Traditional methods often rely on manual labor, which is time-consuming, costly, and prone to errors. ToF cameras, especially iToF (indirect Time-of-Flight) systems, are changing this situation. By leveraging depth-sensing technology, these 3D cameras create detailed maps of crops, which enabling autonomous robots to identify and harvest fruits and vegetables with exceptional accuracy.

Practical Applications of Vzense RGB-D ToF Cameras in Agriculture

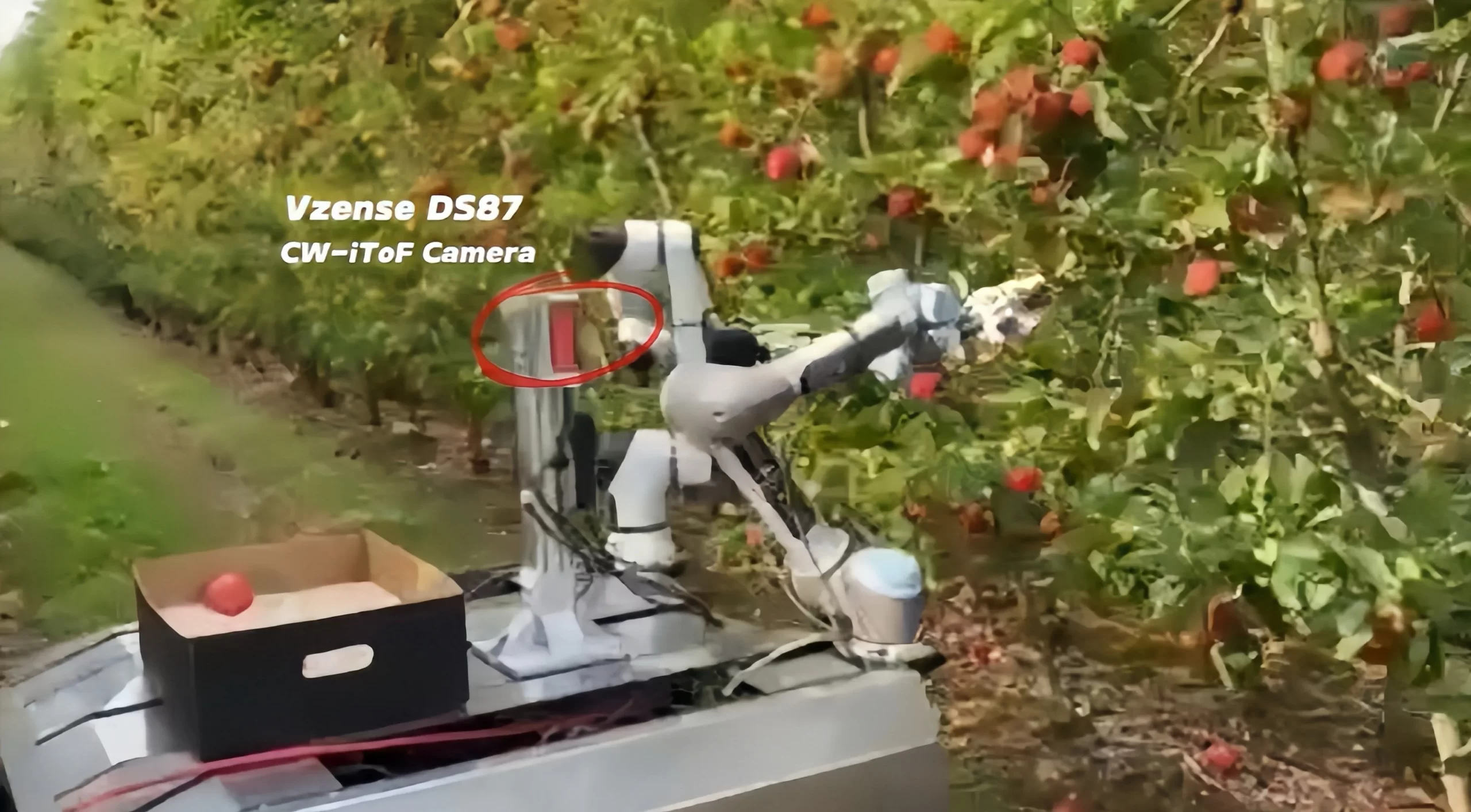

In apple orchards, robotic arms equipped with the Vzense DS87 CW-iToF Camera can precisely detect ripe apples and determine their exact positions in three-dimensional space, which ensures only mature apples are harvested without damaging unripe apples or the trees themselves.

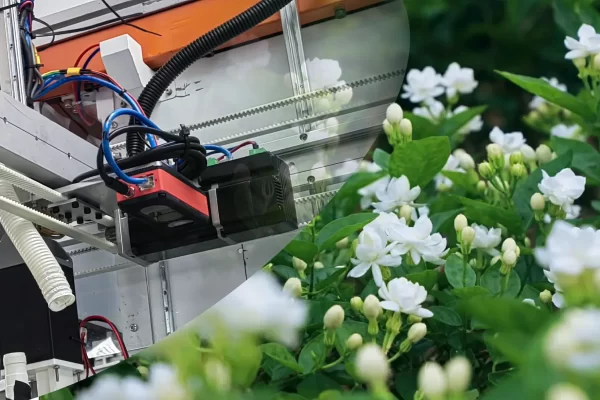

Moreover, our client, inaho Inc., has implemented the DS series 3D camera for asparagus harvesting. Thanks to its exceptional light resistance, the DS series performs reliably in both low-light and high-light conditions, and also its depth sensing, enabling accurate identification and harvesting of asparagus at the optimal height, day or night, Which has not only led to increased yields, reduced waste, but also made significant savings in labor costs.

Crop Monitoring and Yield Estimation with Depth-Sensing Technology

Beyond harvesting, ToF cameras play a vital role in crop monitoring. By capturing depth information, these 3D cameras can track plant growth and health. Farmers can use this data to detect issues such as nutrient deficiencies or diseases early, allowing for timely interventions.

Additionally, 3D cameras are instrumental in yield estimation. By analyzing depth data, farmers can predict harvest volumes, helping those better plan resources and optimize production. This capability is revolutionizing precision agriculture.

Weed Detection and Management Using ToF Technology

Weeds pose a significant challenge in agriculture. Compared to traditional manual detection, ToF technology offers a smarter solution. Using depth perception, 3D cameras can distinguish crops from weeds with remarkable accuracy. This enables more precise herbicide application, reducing chemical usage while saving labor and protecting the environment.

Why Choose Vzense Time-of-Flight Cameras for Agri-Automation?

Traditional agricultural harvesting systems often face the following challenges:

- Low Accuracy: 2D cameras struggle to differentiate fruits from leaves and branches due to the lack of depth information.

- High Costs: Many 3D cameras are prohibitively expensive, making them unsuitable for large-scale agricultural applications.

Limited Performance: Some Time-of-Flight camera suffer from low frame rates or motion blur, hindering their effectiveness in dynamic environments.

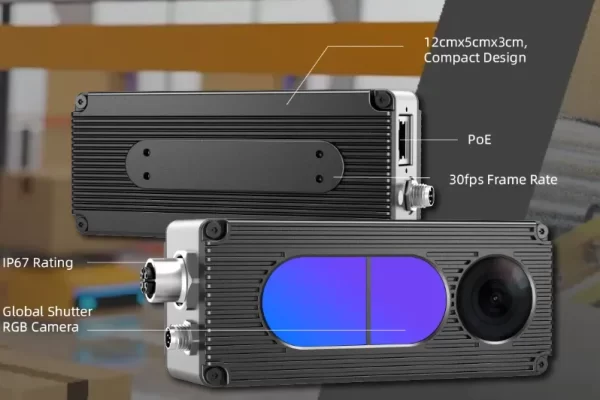

Vzense RGB-D ToF cameras address these issues with the following features:

- High Frame Rate: With a frame rate of up to 30 fps, Vzense 3D cameras can capture fast-moving objects, ensuring reliable performance in dynamic agricultural settings.

- Cost-Effectiveness: Designed to be affordable, Vzense 3D cameras are ideal for large-scale agricultural deployment.

- Dual-Mode Imaging: These cameras simultaneously capture 2D color images and depth maps, providing comprehensive data for fruit detection and localization.

- Customization Capabilities: Vzense ToF cameras offer edge computing capabilities, allowing for tailored solutions to meet diverse agricultural needs, further enhancing harvesting efficiency and reducing costs.

- Automated Harvesting: Autonomous robots equipped with Time-of-Flight camera can perform selective harvesting, ensuring only ripe fruits are picked, minimizing waste, and maximizing yield. By identifying fruit size and color (Figure 5), these systems guide robotic arms to complete the harvesting process.

By integrating Vzense RGB-D ToF cameras, agricultural harvesting has become smarter, more convenient, and highly efficient.

If you’d like to learn more about our 3D camera technology, feel free to explore our previous articles. Additionally, Goermicro Vzense will showcase two high-performance, cost-effective ToF products: DS series and NYX series at the Automate exhibition hosted by the Association for Advancing Automation (A3) this May. We welcome you to visit our booth and look forward to receiving your valuable feedback!