Overview

Beyond capturing images in the X and Y directions, Time-of-Flight (ToF) Cameras also gather Z direction data, allowing for 3D sensing.

This 3D capability makes it possible to detect features that are challenging with traditional 2D images, such as inspecting based on volume or shape and identifying overlapping objects.

Additionally, it’s a promising technology for real-time applications requiring relative distance information, like automated control or collision avoidance systems. Automation and manpower reduction are rapidly expanding across various sectors in the industrial equipment domain.

This includes the modernization of manufacturing lines, logistics systems, agriculture, and farming. ToF image sensors, compact and capable of immediate 3D data acquisition, are expected to be widely used across numerous applications due to their ability to meet increasing demands for recognition, measurement, and automation.

Why Goermicro?

With the most competitive advantage of versatility. Goermicro ToF camera can be used in a wide range of applications, from detecting the presence of objects to monitoring entire assembly lines. This flexibility makes them ideal for use in smart logistics, robot safety, level monitoring, load monitoring, mobile robots, and smart health.

Versatility

Accuracy

Speed

Low cost

Robust

Various Types of Automation

Smart Logistics

Smart logistics refers to the use of advanced technologies and data-driven approaches to optimize the management of supply chains and logistics operations. This includes the automation of processes, real-time tracking of goods, and efficient resource allocation to improve the speed, accuracy, and overall efficiency of logistics.

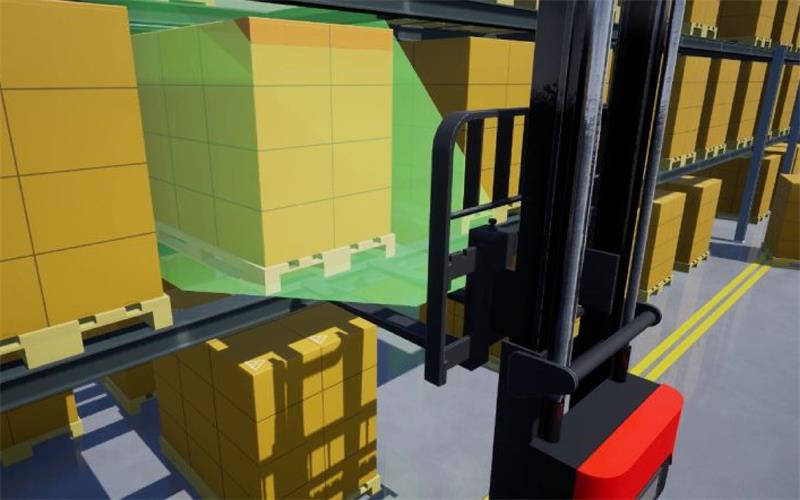

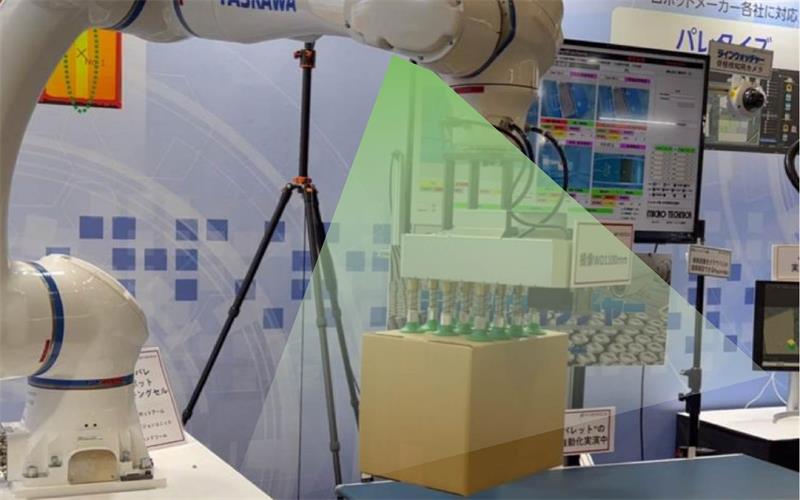

Goermicro iToF cameras play a crucial role in smart logistics due to their ability to capture precise 3D data and high frame rate up to 30 fps. Our 3D cameras provide accurate distance measurements and real-time tracking, which are essential for effective inventory management and pallet recognition.

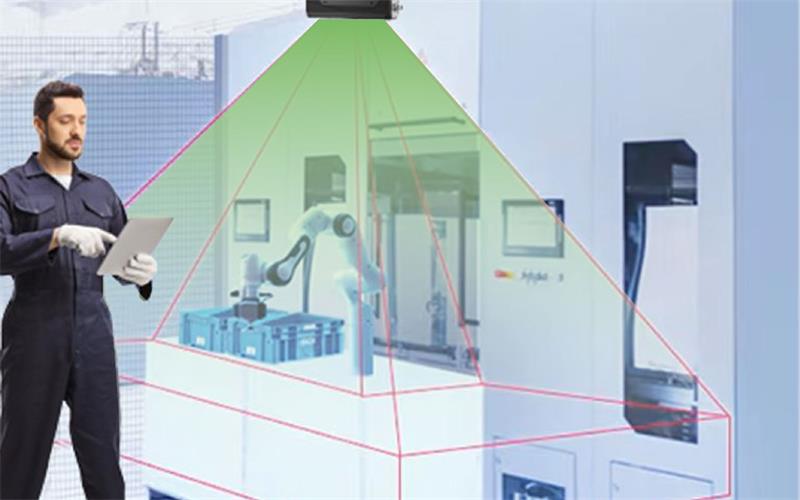

Robot Safety

With the widespread adoption of factory automation, more “dark factories” are emerging. Ensuring the safety of workers and inspectors by equipping automatic safety devices for various factory equipment in low-light environments has become a challenge for enterprises. Fortunately, Goermicro ToF cameras can perfectly solve this problem. Our Time of Flight (ToF) cameras emit their own laser and have a very high signal-to-noise ratio, allowing them to accurately identify whether someone has entered the operating area in low-light conditions and whether their posture or movements pose any safety risks. This enables the cameras to convey precise image information to the machine controllers, allowing the machines to decide whether to slow down or stop, ensuring operational safety.

Level Monitoring

Level monitoring refers to the process of measuring and controlling the level of liquids, solids, or gases within a container or system. It is a crucial aspect of many industrial processes, ensuring that tanks, silos, and reservoirs maintain optimal levels for safety, efficiency, and quality control.

Goermicro ToF cameras are widely adaptable for level monitoring applications and are favored by many customers. This is because our ToF cameras are highly accurate, emit their own light, and exhibit strong environmental robustness. They are suitable for long-term use in various harsh industrial environments or enclosed, dark spaces.

Load Monitoring

Load monitoring involves measuring and tracking the load (weight or force) applied to structures, machinery, or components in various industrial applications. It’s essential for ensuring safety, efficiency, and optimal performance. It is widely used in industries such as construction, manufacturing, transportation, and energy to ensure that systems and components operate safely and efficiently. Goermicro iToF cameras can significantly enhance load monitoring by providing accurate, real-time 3D data.

For AGV/AMR

Automated Guided Vehicles (AGVs) and Automatic Mobile Robots (AMRs) are key technologies in industrial automation. AGVs are used in manufacturing and warehouses for transporting materials along predetermined paths. AMRs are advanced robots that navigate and perform tasks autonomously using sensors like LiDAR, cameras, and GPS, along with AI algorithms.

Goermicro ToF cameras enhance both AGVs and AMRs by providing accurate 3D data for navigation, obstacle detection, and real-time decision-making. These cameras improve safety, efficiency, and adaptability in various environments by offering precise depth sensing and environmental mapping.

Smart Healthcare

Fall detection is a new application area in smart home security, designed to promptly identify and issue warning signals when the target individual falls. Previously, it primarily relied on sensors like accelerometers and gyroscopes to detect sudden movements and impacts consistent with a fall, but it often resulted in false alarms and misjudgments.

Goermicro Time-of-Flight cameras provide precise 3D depth data, enhancing the accuracy of fall detection by capturing detailed information about the environment and the person’s movements.

Discover More Applications

-

For AGV/AMR

Explore More -

People Counting

Explore More -

Item Picking

Explore More -

Automation

Explore More