Accurate and efficient material level monitoring is crucial in various industrial automation scenarios—from bulk material storage to production line control. Time-of-Flight (ToF) cameras, as an advanced form of 3D camera technology, are increasingly being adopted to meet these demanding requirements with enhanced flexibility, real-time performance, and depth sensing precision.

Table of Contents

The Role of ToF Cameras in Industrial Automation

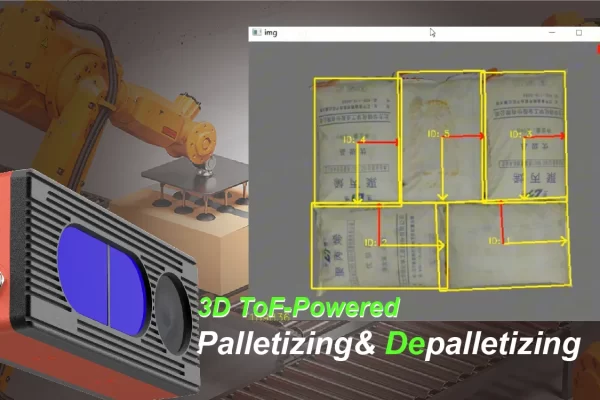

Traditional methods of level monitoring—such as ultrasonic sensors, mechanical switches, or 2D vision—often struggle with accuracy in dusty, dark, or reflective environments. In contrast, Time-of-Flight (ToF) cameras use the time delay of reflected infrared light to calculate distances, generating real-time depth maps across the entire scene. This capability allows ToF cameras to operate reliably even in low-light or high-dust conditions common in industrial settings.

Thanks to their compact design and ability to capture full-frame depth images in milliseconds, iToF (indirect Time-of-Flight) systems are particularly suited for continuous, non-contact material level detection.

Why Use the 3D Camera for Level Monitoring?

Employing a 3D camera for level monitoring enables:

- Non-intrusive, real-time sensing: Unlike mechanical contact-based solutions, ToF cameras monitor material levels without physical contact, reducing wear and tear.

- Full-field analysis: With one capture, a ToF camera can assess the entire surface of a silo, tank, or container—minimizing blind spots.

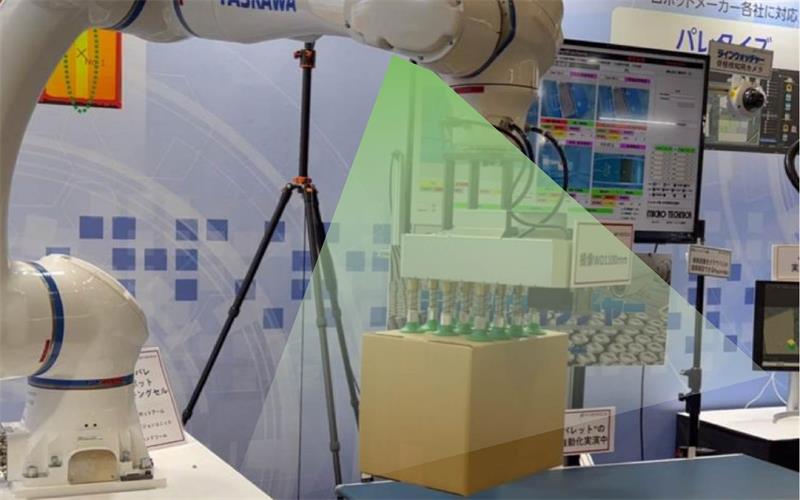

- Flexible deployment: ToF cameras can be installed at various heights and angles, with adjustable regions of interest (ROI), making them ideal for complex or constrained spaces.

These features make Time-of-Flight cameras a valuable component of smart factories, where efficiency and automation go hand-in-hand.

Key Benefits of Time-of-Flight Cameras in Level Monitoring

- Accurate depth sensing even for irregular material surfaces (e.g., gravel, powder, granules).

- Millisecond-level response time, supporting frame rates up to 30 fps for real-time feedback.

- High adaptability in harsh environments, with industrial-grade enclosures (e.g., IP67) and wide temperature tolerance.

Combined, these features help reduce downtime, improve inventory management, and enable predictive maintenance strategies in industrial environments.

Practical Application Scenarios

1. Silo and Bin Monitoring

In industries such as agriculture, mining, and food processing, ToF cameras can be mounted above large silos or bins to continuously monitor fill levels. The 3D depth sensing capability allows the system to detect uneven surfaces and provide volume estimation with high accuracy, regardless of dust, vibration, or lighting.

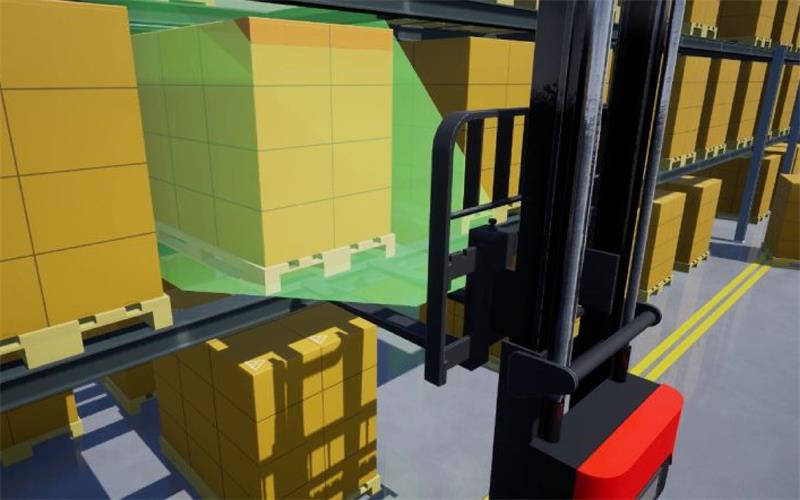

2. Production Line Buffer Zone Monitoring

In manufacturing lines where materials temporarily accumulate between processing steps, a ToF 3D camera can help track overflow risks or shortages in real time, triggering automated responses such as conveyor start/stop or supply alerts.

3. Liquid Level Detection in Transparent Tanks

By tuning the sensing parameters and ROI, ToF cameras can approximate liquid levels in semi-transparent tanks—something traditional 2D systems often misread due to reflections or refractions.

Considerations for Deployment

To achieve optimal performance, consider the following when deploying ToF cameras:

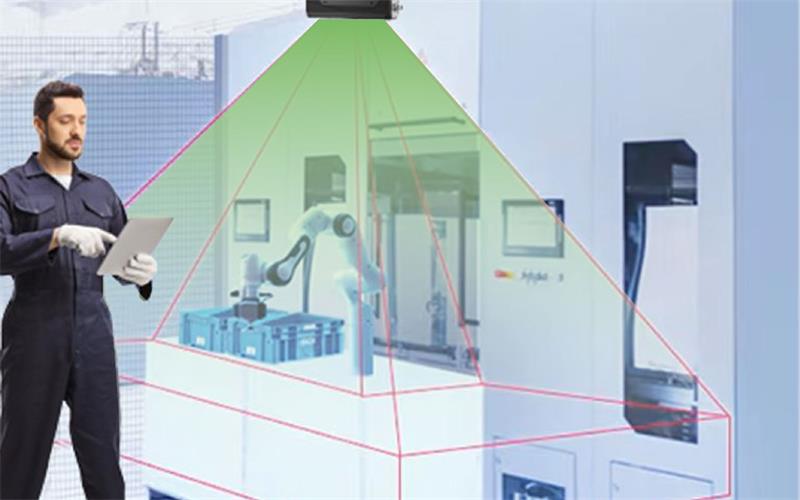

- Installation height and FoV: A wider field of view (FoV) captures more area but may trade off some resolution.

- ROI customization: Defining a specific sensing zone helps focus detection and avoid background noise.

- Multi-frame fusion: Combining multiple frames can improve robustness in noisy environments.

These technical adjustments leverage the underlying iToF principles while maintaining a seamless user experience.

Outlook: Time-of-Flight Cameras in Smart Industry 4.0

As industrial automation evolves toward more autonomous and intelligent systems, the demand for reliable, scalable, and cost-effective 3D vision solutions continues to rise. ToF cameras, with their real-time 3D sensing capabilities and compatibility with modern edge computing systems, offer a future-proof path for smart monitoring solutions.

Interested in deploying ToF-based level monitoring in your factory?

Contact with us to learn more about customizable solutions using Vzense’s industrial-grade 3D cameras.