In the busy operations of factory workshops and the round-the-clock work in logistics warehouses, a solid perimeter security barrier stands as the first line of defense for protecting equipment, personnel, and core operations. But traditional fence protection is like a “sluggish sentinel”: it either triggers false alarms from swaying branches in the wind or often responds sluggishly when faced with intruders trying to climb over.

Today, with breakthroughs in 3D sensing technology, this line of defense is being redefined. And in this wave of security upgrades, Goermicro’s Time-of-Flight (ToF) cameras are emerging as the “driving force behind the scenes” — how do they transform industrial fences from “passive defense” to an “active early warning” impenetrable wall? Behind this lies the core secret that maximizes protective power.

Table of Contents

From “2D Monitoring” to “3D Perception”: The Security Code of ToF Technology

The core demand for industrial security is straightforward: accurately detect “uninvited guests” while minimizing the hassle of false alarms for security personnel. With traditional solutions, 2D cameras only capture flat images, unable to distinguish between a worker 3 meters outside the fence and an intruder 1 meter from it. Infrared sensors are even more “confused” — a falling leaf can trigger an alarm.

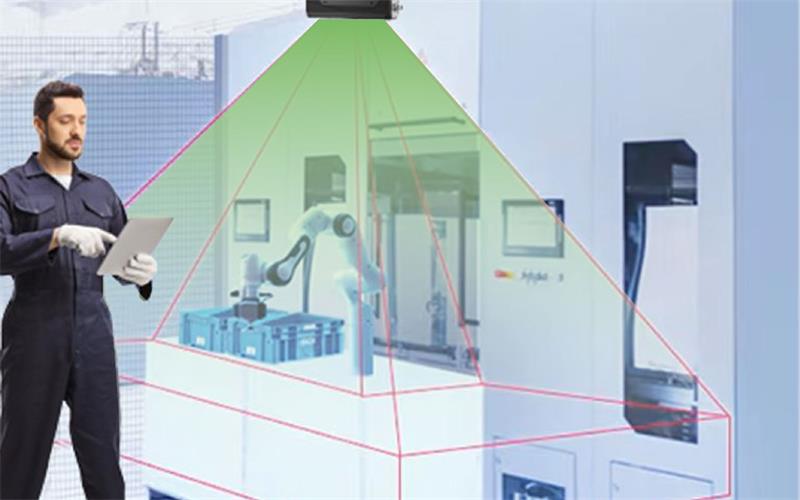

The arrival of ToF cameras has rewritten the rules of this monitoring game. Its working principle is like equipping the fence with a pair of “3D perspective eyes”: actively emitting light signals, calculating the time it takes for the signals to reflect back, instantly determining the distance, position, and movement trajectory of objects relative to the fence, and ultimately generating a real-time updated 3D spatial map.

This 3D perception capability is precisely the key to ToF cameras solving the “high false alarms and poor judgment” issues of traditional solutions — it doesn’t just “see,” but can “understand” every detail in the scene.

Five Core Advantages That Maximize Fence Protection

Among numerous 3D products and solutions, Goermicro stands out with its highly competitive solution — LumiGuard. Its core competitiveness stems from our four key advantages:

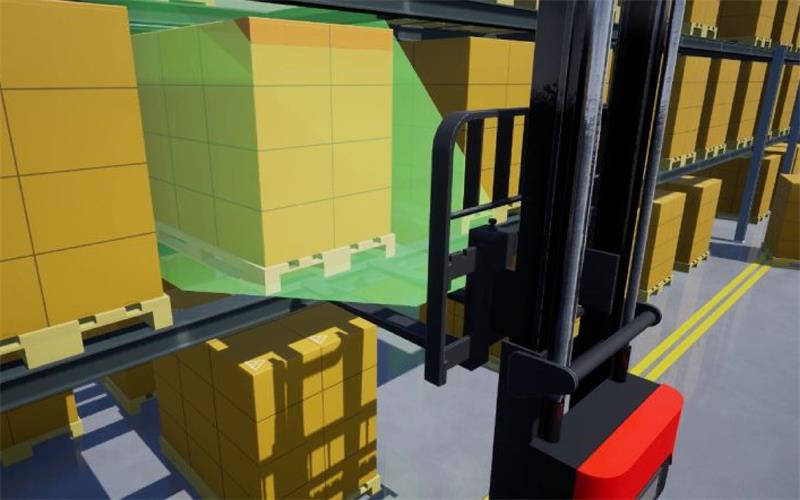

- Omnidirectional Depth Perception: Even if an object tries to crawl through a 10-centimeter gap at the bottom of the fence, Goermicro’s LumiGuard ToF camera can accurately detect it through distance changes, avoiding the “blind spot missed detection” problem of traditional devices.

- Millisecond-Level Real-Time Response: With 30fps high frame rate monitoring, the entire process from detecting an anomaly to issuing an alarm takes no more than 0.5 seconds. This minimizes the intruder’s reaction time and allows security personnel to intervene faster.

- Environmental Robustness: Whether in direct noon sunlight, low-light conditions at night, or even light rain and mist, the light signals of our ToF cameras remain unaffected, maintaining stable monitoring at all times. Compared to the shortcoming of traditional 2D cameras that “stop working in the dark,” it can be called an “all-weather bodyguard.”

- Low Deployment Cost: The LumiGuard ToF camera has a working distance of up to 4.5 meters and a field of view (FoV) of 70°(H)*50°(V). A single camera can monitor an approximately 3×4-meter security area. In terms of cost, it is about 60% lower than traditional solutions.

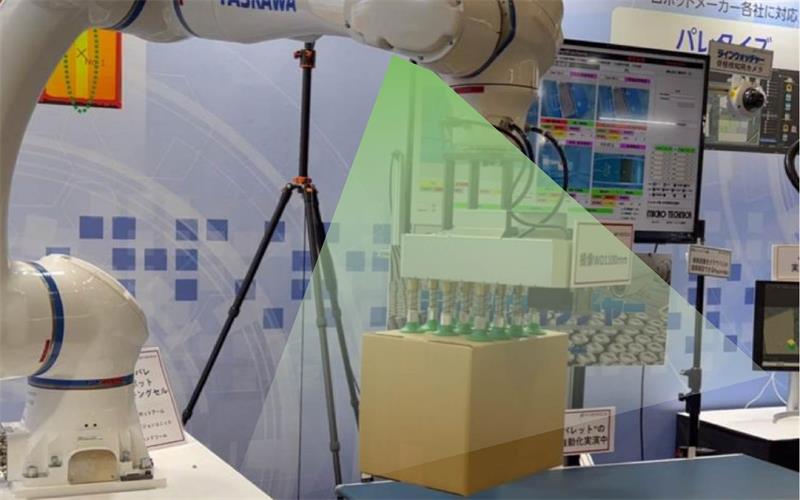

- Flexible Settings: A single device can be set with multiple monitoring zones, which are prioritized according to security levels to output different levels of security response commands. For example: setting different security zones around robotic arms, and outputting deceleration or shutdown commands based on personnel entering specific zones, ensuring personnel safety while maintaining production efficiency!

These combined advantages transform industrial fences from “isolated physical barriers” into intelligent defense lines that “perceive, judge, and respond.”

What Makes LumiGuard Truly Stand Out?

Let’s draw a straightforward comparison: Traditional fence systems rely on 2D images and basic sensors, struggling to distinguish object distances and intentions, resulting in crude judgments. In contrast, Goermicro’s LumiGuard solution, leveraging ToF technology, precisely marks distances and trajectories with 3D depth data, verifies actual threats, and delivers far more reliable assessments.

| Traditional Fence Solutions | Goermicro’s LumiGuard Solutions |

| Rely on 2D images, hard to determine object – fence distance | 3D depth data shows distance and intrusion clearly |

| Light, wind, etc. easily trigger false alarms (high rate) | Intelligently distinguishes interference & threats, false alarm rate < 0.1% |

| Complex wiring, many devices, high maintenance cost | Supports wireless deployment, fewer durable devices, lower long – term cost |

| Only “alarm”, hard to link with other systems | Can connect to industrial automation platforms, collaborate with AGVs etc. |

Take a large manufacturing park as an example: a traditional system might trigger an alarm when a bird flies past the fence, sending security personnel on a fruitless trip. In contrast, Goermicro’s 3D ToF camera can directly classify it as a “non-threat” based on 3D features such as volume, flight altitude, and speed, allowing security efforts to focus on real risks.

Beyond Just “Prevention”: ToF Technology and Industrial Automation “Fight in Synergy”

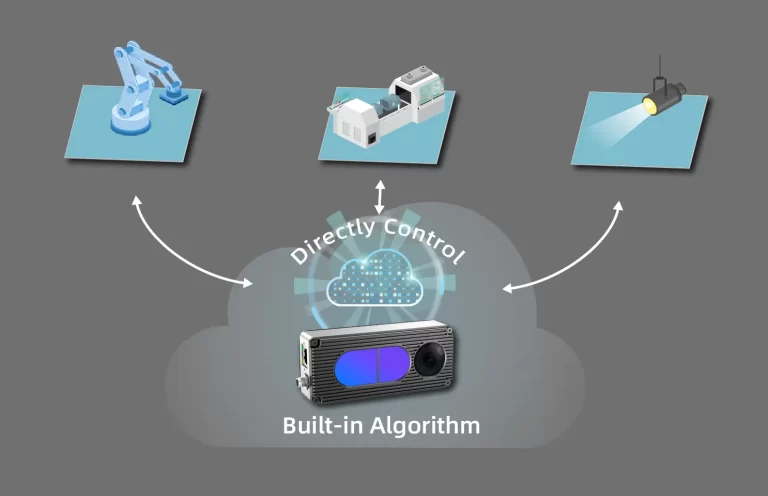

The highest realm of modern industrial safety is that safety and production neither conflict with each other nor even empower one another. Goermicro ToF cameras demonstrate a unique advantage in this regard — they are not just isolated monitoring devices but can be integrated into the large ecosystem of industrial automation.

When a ToF camera detects an abnormal intrusion near the fence, besides triggering a local alarm, it can also synchronize data to the AGV scheduling system of the park in real time, making the unmanned transport vehicles operating nearby automatically slow down and detour to avoid collision risks. In sensitive areas such as dangerous goods warehouses, it can even link with the access control system. Once unauthorized approach is detected, the relevant passages are immediately locked, forming a closed loop of “monitoring – response – disposal”.

Goermicro’s LumiGuard solution is precisely designed for this purpose: Equipped with high-precision output IO ports, it can respond in real time and output control signals, and can be seamlessly linked with other security devices (such as alarms, cameras, access control systems, etc.). It enables safety data and production data to be presented on the same dashboard, facilitating managers to have overall control.

The Future Is Here: ToF Technology Drives Continuous Evolution of Fence Protection

As Industry 4.0 advances, the protection needs of industrial fences are escalating — from “intrusion prevention” to “risk prediction,” and from “single-point monitoring” to “full-area joint defense.” ToF technology is rapidly iterating toward these directions.

For instance, when integrated with AI algorithms, Goermicro ToF cameras can learn from historical data to predict “which time periods and areas are prone to intrusion risks” and adjust monitoring sensitivity in advance. Another example is the linkage with IoT devices; future industrial parks may realize a full-area 3D monitoring network combining “fences, cameras, and drones,” leaving no anomalies undetected in any corner.

Goermicro has already taken a leading step in technical layout: the hardware design of its LumiGuard solution reserves space for algorithm upgrades, and the software platform supports multi-device collaboration, enabling continuous expansion as enterprises’ security needs grow, thus keeping protection at maximum capacity.

For modern industrial facilities pursuing efficiency and safety, choosing ToF technology is not just adding a layer of “smart armor” to fences, but also injecting “evolutionary genes” into the entire park’s security strategy — which may well be the ultimate answer to the soaring security levels.

For more insights into innovative applications of 3D ToF technology in industrial scenarios and industry news, you can follow our LinkedIn account or YouTube channel.