Table of Contents

1. Why Black Pallets Are the Ultimate “Stress Test” for 3D Vision

In modern logistics and warehousing, accurate pallet recognition and positioning are critical for AGVs to achieve unmanned operation and high efficiency.

More than 80% of pallets used in warehouses are black plastic pallets.

However, traditional vision solutions often struggle with black pallets due to:

- Extremely low reflectivity

- Strong light absorption of plastic materials

- Severe interference from ambient lighting

These challenges lead to unstable detection, false recognition, or even missed targets—directly reducing AGV operational efficiency and system reliability.

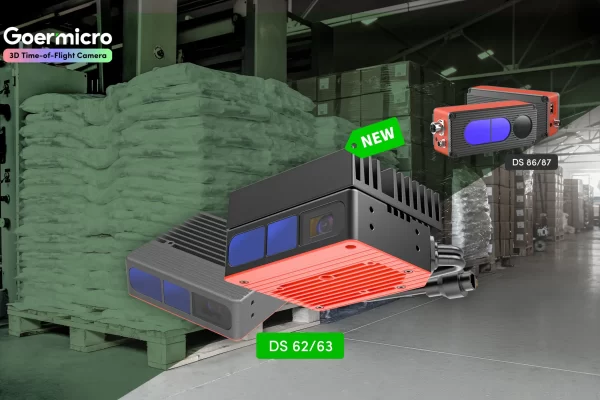

Goermicro 3D ToF RGB-D depth cameras provide a truly industrial-grade solution.

Unaffected by material color or lighting conditions, black pallets can be detected clearly, accurately, and consistently.

2. How Goermicro Easily Overcomes the “Black Pallet Challenge.”

Goermicro 3D ToF cameras combine:

- 940 nm near-infrared active illumination

- Wide dynamic depth sensing

- Pulsed iToF (Indirect Time-of-Flight) technology

This architecture enables precise point-cloud output even on low-reflectivity surfaces. Whether under strong sunlight, low-light environments, or on black materials, depth data remains stable and accurate.

In addition, unlimited multi-camera coexistence and IP67 industrial protection allow Goermicro depth cameras to operate reliably in high-density AGV deployments and harsh industrial environments—making black pallet recognition truly standardized and scalable.

3. Four Key Advantages Designed for Mobile Robots

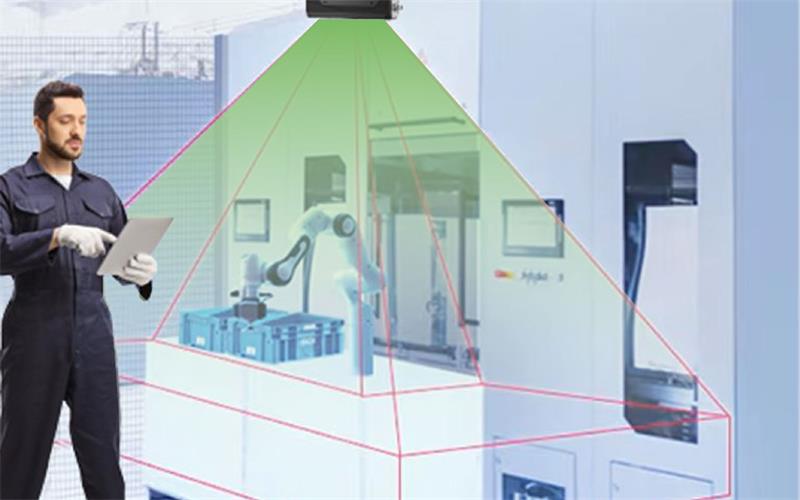

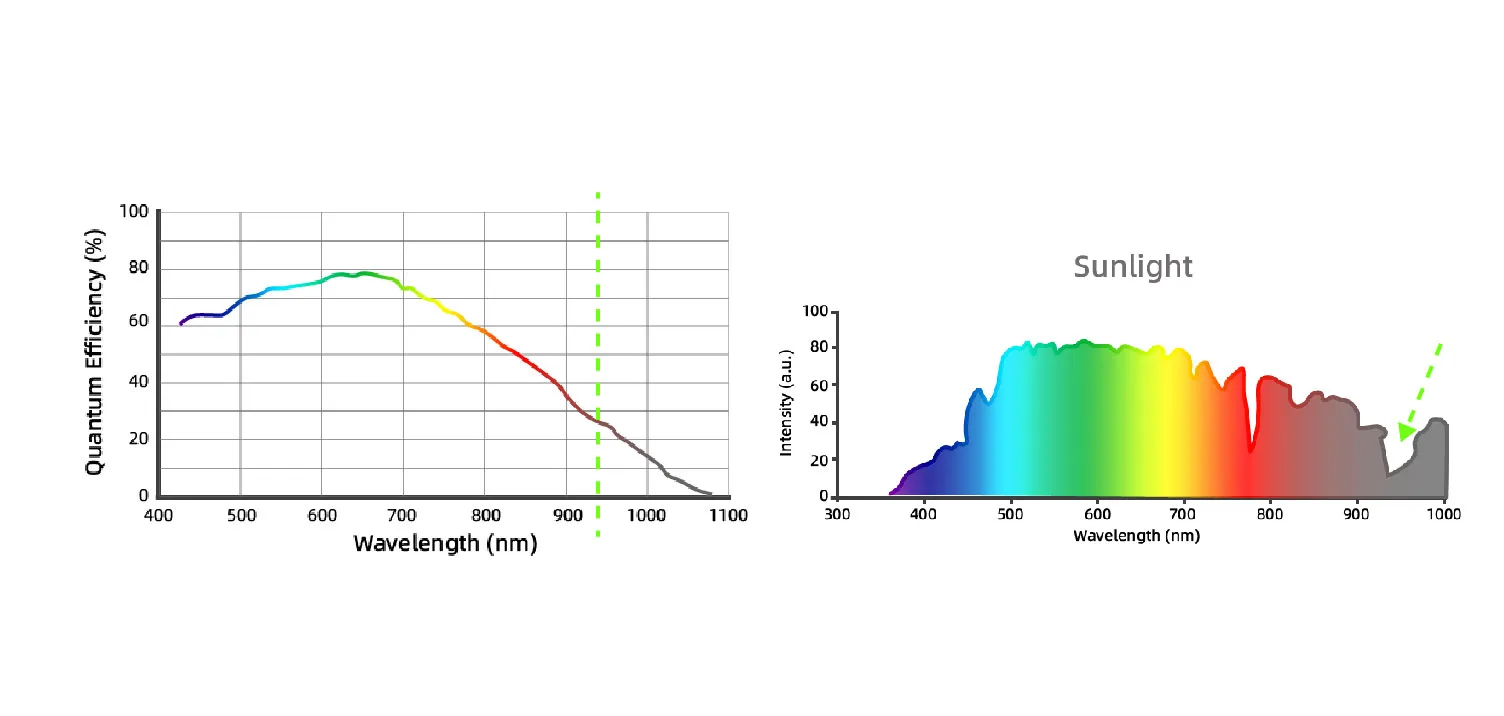

01. 940 nm Active Illumination

Stronger resistance to ambient light

Goermicro’s self-developed 3D ToF cameras use 940 nm near-infrared active illumination, which is well separated from visible light wavelengths.

This allows stable depth output even under:

- Direct sunlight from warehouse skylights

- High-intensity factory lighting

- Indoor–outdoor transitions

No additional lighting equipment is required—reducing system complexity, deployment costs, and improving reliability.

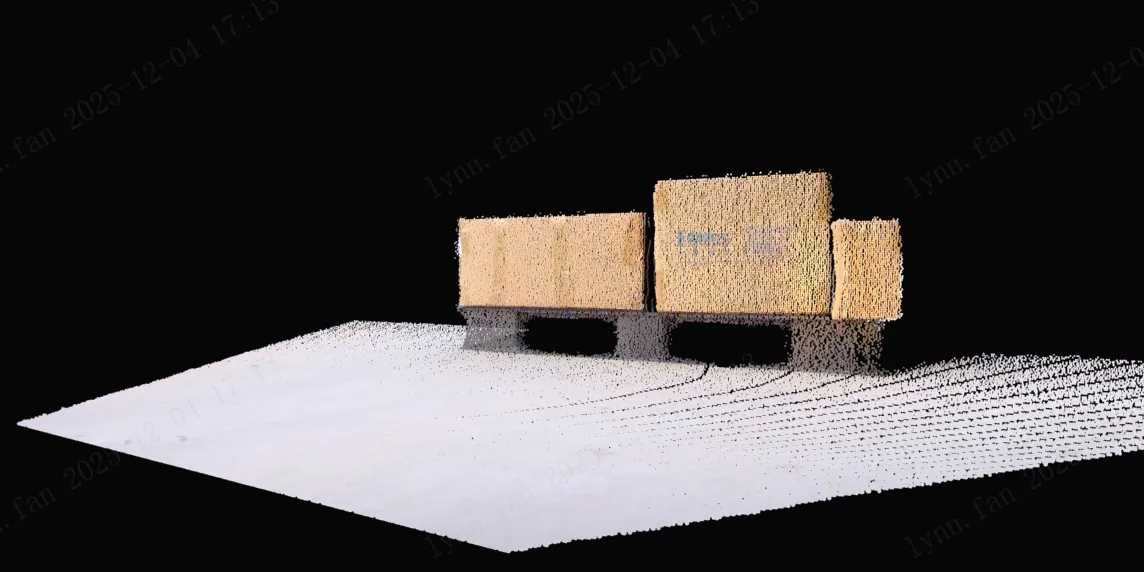

02. Wide Dynamic Range

Accurate depth even on black pallets

Conventional vision systems often fail to extract depth from black surfaces due to weak signal return.

Goermicro’s NYX series pulsed iToF cameras feature wide dynamic depth sensing, enabling high-precision depth acquisition from both near and distant low-reflectivity objects.

This ensures complete and accurate contour reconstruction of black pallets.

Color-independent. Lighting-independent. Reliable depth data—every time.

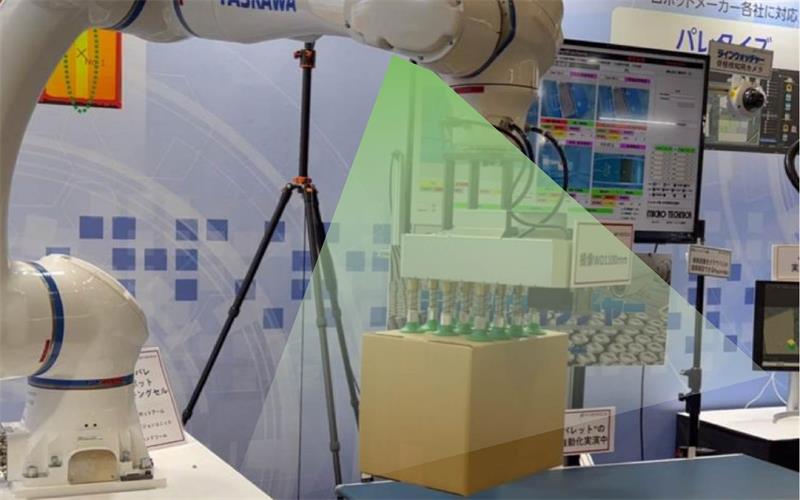

03. Pulsed iToF Architecture

Unlimited multi-camera coexistence

The innovative pulsed iToF design allows multiple cameras to operate in the same space without mutual interference.

Even in scenarios with many AGVs running simultaneously, depth data remains stable—making it ideal for high-density warehouse automation and truly scalable unmanned systems.

04. IP67 Industrial Protection

Built for real-world environments

Designed to industrial standards, Goermicro depth cameras can be directly deployed in:

- Warehousing and logistics centers

- Cold-chain environments

- Outdoor or semi-outdoor applications

They withstand dust, oil contamination, water spray, condensation, and other industrial challenges—meeting real AGV frontline deployment requirements.

4. Enabling Multiple AGV Applications

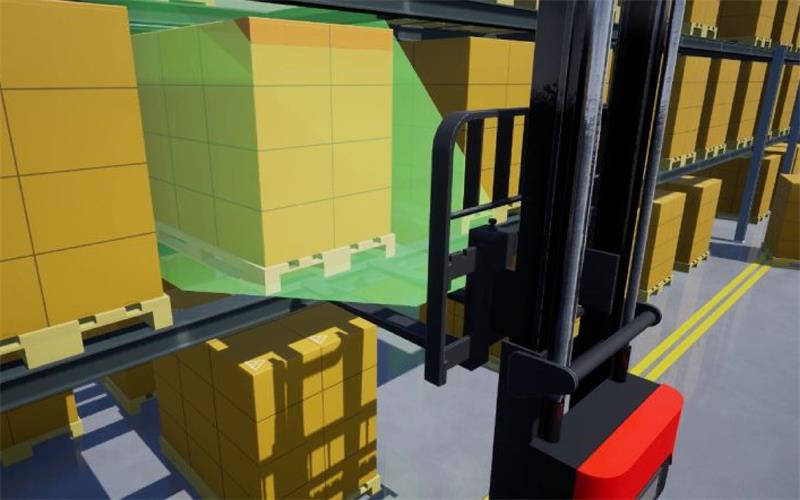

✔ AGV obstacle avoidance

✔ Autonomous forklift pallet recognition

✔ Pallet stacking and height detection

✔ Warehouse AGV path planning

From standard pallets to non-standard pallets, and from reflective to black materials that traditional cameras struggle with, Goermicro delivers stable, high-accuracy recognition—ready for seamless integration into AGV systems for automated picking, transport, and stacking.

Helping AGVs See the World More Intelligently

Goermicro 3D ToF RGB-D cameras empower AGVs with reliable depth perception, regardless of pallet color or lighting conditions.

If you’re looking for a solution that truly solves black pallet recognition challenges.

Contact us to learn more.