Table of Contents

Industry Insight: Perception Bottlenecks in Flexible Production

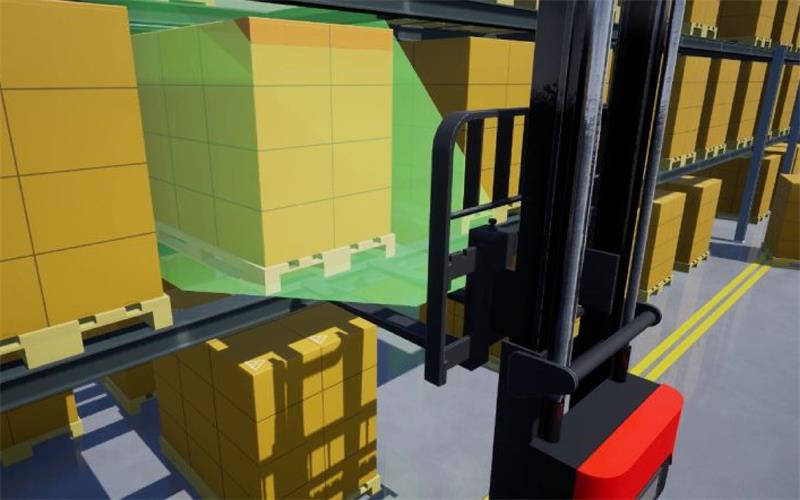

As Industry 4.0 and smart warehousing become ubiquitous, production lines are rapidly shifting toward flexible manufacturing. The diversity of materials, random stacking, and high-frequency operating cycles present rigorous challenges to robotic vision.

Traditional 2D vision solutions lack depth information, making it difficult to balance perception accuracy and operational efficiency when faced with complex lighting or disordered, overlapping objects. The industry urgently requires a new generation of vision-guided solutions characterized by precise 3D perception, high robustness, and rapid deployment.

Core Solution: Goermicro 3D ToF Full-Stack Vision Guidance

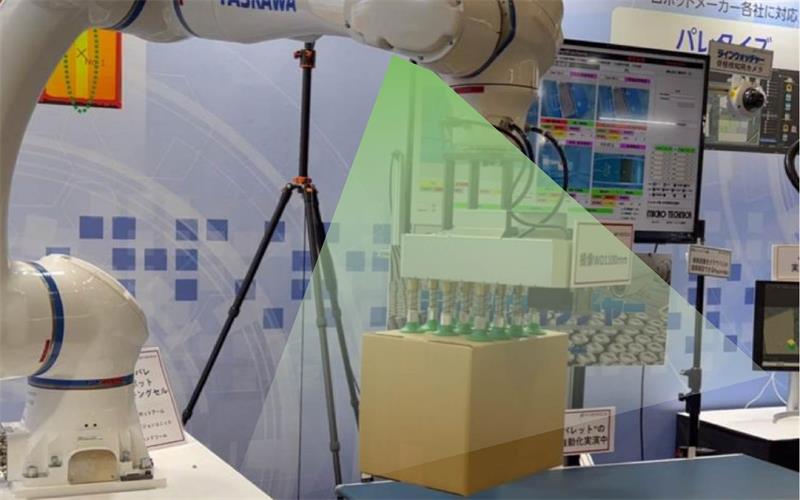

Addressing these pain points, the Goermicro 3D ToF team leverages its deep heritage in optical sensing to launch the Proprietary 3D ToF Vision-Guided Automated Palletizing and Depalletizing Solution.

This solution equips industrial robots with precise “3D vision,” enabling intelligent guidance for the accurate picking and placing of cartons, soft bags, and other materials across pallets, conveyors, and sorting equipment. It is widely applicable in logistics, e-commerce, food, and daily chemicals, serving as a technical cornerstone for enterprises building agile, efficient, and unmanned smart logistics systems.

Hardware Innovation: The DS Series ToF Camera Matrix

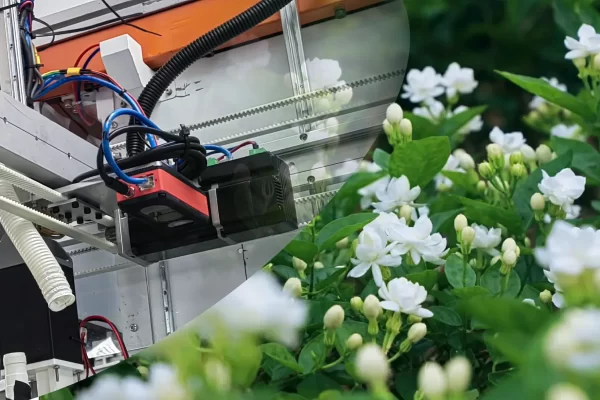

Superior algorithms require exceptional hardware. Currently, the full range of Goertek Micro’s DS series ToF cameras is perfectly adapted to this palletizing algorithm.

The Foundation: The DS 86/87 continues to provide high-stability service for frontline scenarios.

The Flagship: Goermicro will officially launch the DS 62/63, featuring the Infineon IRS2976C ToF image sensor.

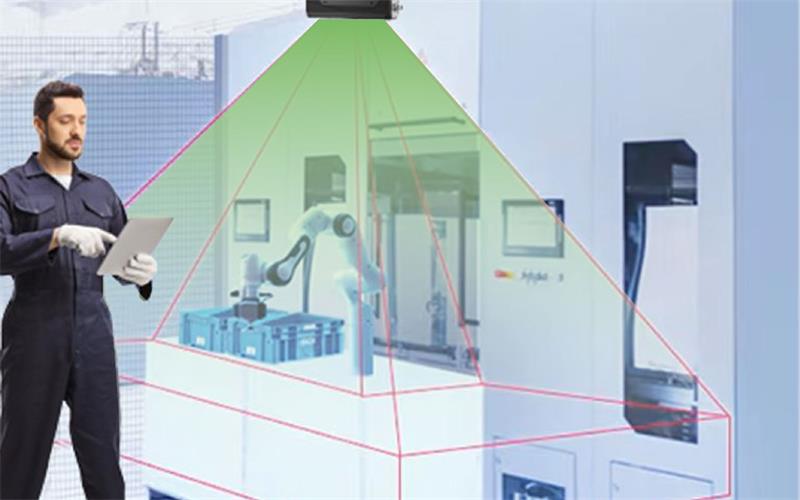

Compared to previous generations, the DS 62/63 achieves a balance of high cost-performance, high frame rates, and a wide Field of View (FOV) within a more compact form factor. For complex “Eye-in-Hand” systems—where space at the end of the robotic arm is limited and high-speed, continuous operation is required—the DS 62/63 is the premier choice for perception.

Precision Algorithms: A Closed Loop from Perception to Execution

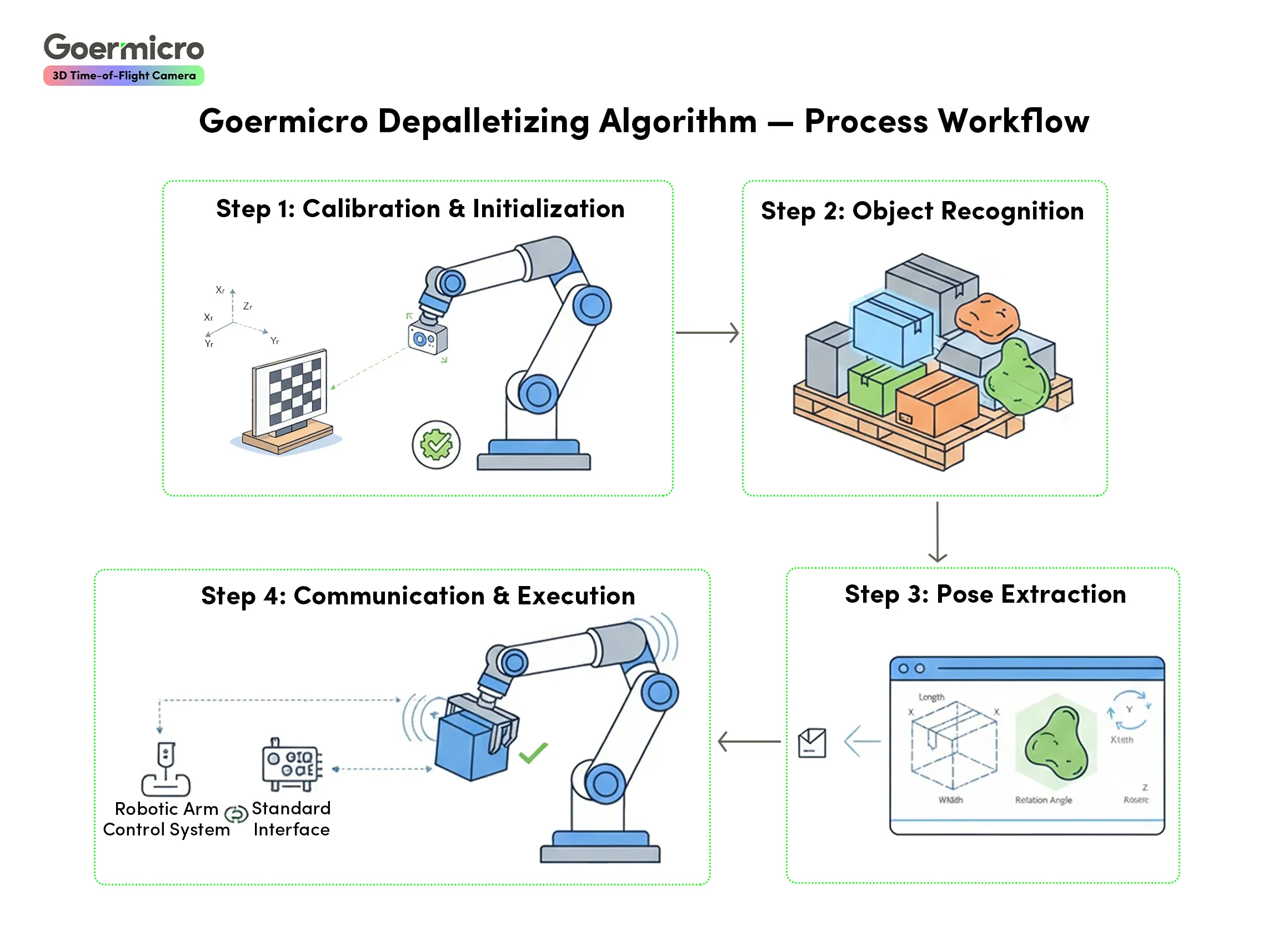

Goermicro’s proprietary algorithms optimize the entire workflow to ensure “perception-is-execution” efficiency:

- High-Precision Hand-Eye Calibration: Establishes a precise mapping between the 3D ToF camera and the robotic arm, ensuring millimeter-level pose coupling between data and action.

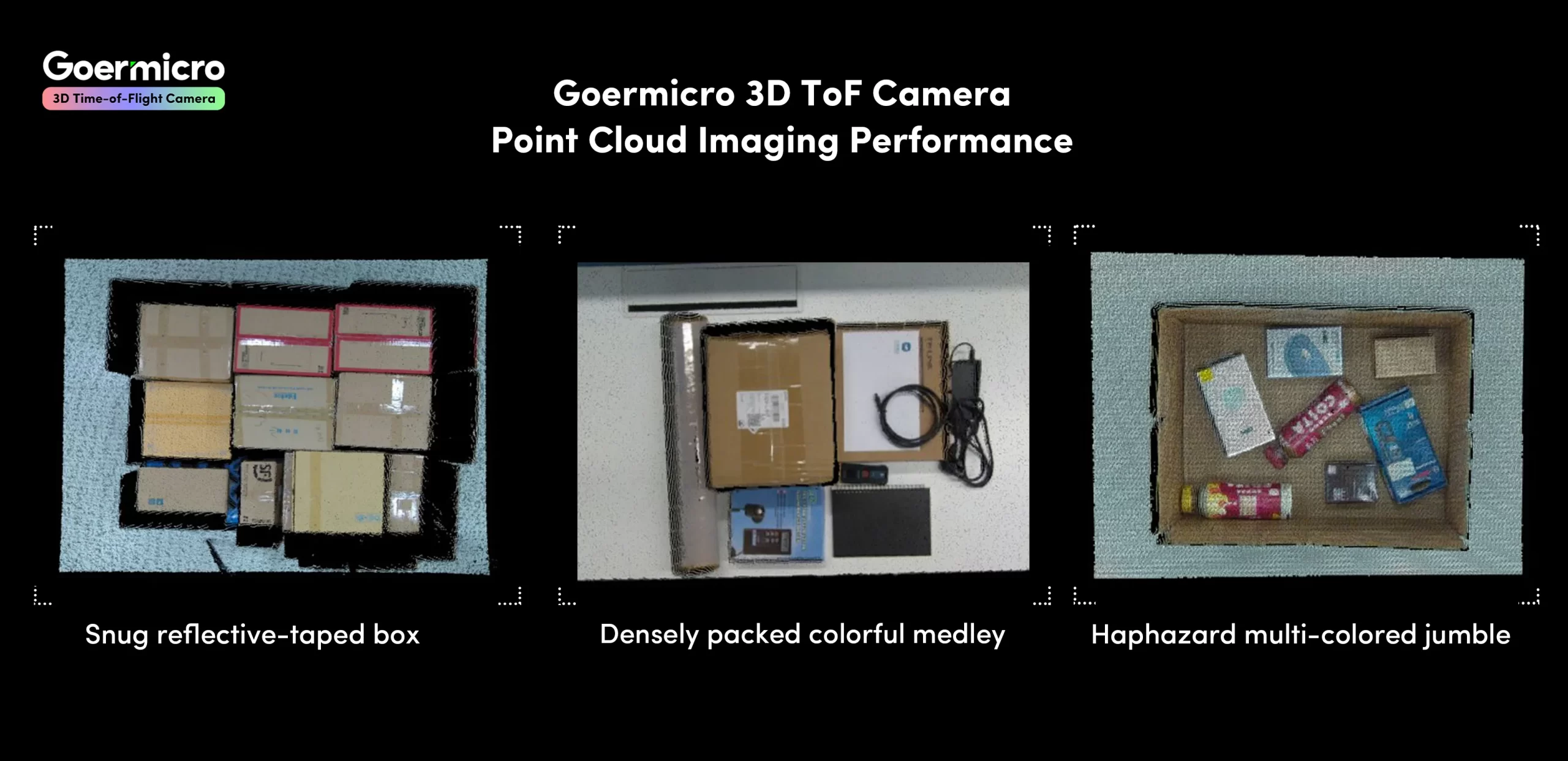

- Intelligent Object Recognition: Utilizing real-time depth point clouds, the algorithm autonomously identifies and distinguishes between rigid cartons and soft bags, maintaining exceptional robustness even in random or disordered stacking conditions.

- Multi-Dimensional Pose Analysis: Accurately calculates dimensions (length/width), 3D center coordinates, and XY-plane rotation, providing comprehensive data support for robotic grasping decisions.

- Dynamic Linkage & High-Speed Execution: Fully compatible with TCP and Modbus protocols, ensuring low-latency, highly reliable data transmission from the vision terminal to the control system.

Solution Highlights: Empowering Industrial Scenarios

Resilient Perception: Combines advanced ToF technology with HDR (High Dynamic Range) to maintain reliable depth capture under strong light or complex backgrounds.

Lightweight Design: Compact body with ultra-low power consumption (<5W), ideal for end-of-arm installation to reduce load and enhance system flexibility.

Hardware-Software Synergy: Algorithms are deeply optimized for DS-series hardware, significantly increasing recognition speed and success rates for a true “out-of-the-box” experience.

Open Ecosystem: Provides cross-platform SDKs (Windows/Linux/ROS) and multi-language support (C++/Python), drastically shortening secondary development cycles.

Cost-Efficiency: Compared to structured light or high-end LiDAR, the Goermicro ToF solution offers a superior performance-to-cost ratio.

Goermicro remains committed to injecting “intelligence” into automated equipment through sensor innovation.

For detailed specifications on the DS 62/63 or a demonstration of our palletizing algorithms, please contact our technical experts.