With the ongoing advancement of smart mining, accurate coal flow data serves as the foundation for digitalized production. From extraction and transportation to dispatching, every stage depends on real-time, precise flow monitoring to ensure safe, efficient, and controllable operations.

Table of Contents

Challenges in Traditional Coal Flow Measurement

Conventional methods such as nuclear belt scales and electronic belt scales face significant challenges in modern mining environments:

- High safety risks: Nuclear detection relies on radioactive sources, which are strictly regulated and potentially hazardous.

- Low efficiency: Mechanical systems require frequent calibration, suffer from wear and drift, and are difficult to maintain.

- Environmental interference: Dust, vibration, and varying light conditions often lead to unstable or inaccurate measurements.

- High maintenance costs: Contact-based systems increase downtime and reduce productivity.

These issues make it difficult to achieve continuous, accurate, and safe coal flow monitoring, highlighting the need for a non-contact, intelligent, and reliable solution.

Goermicro ToF Camera Solution

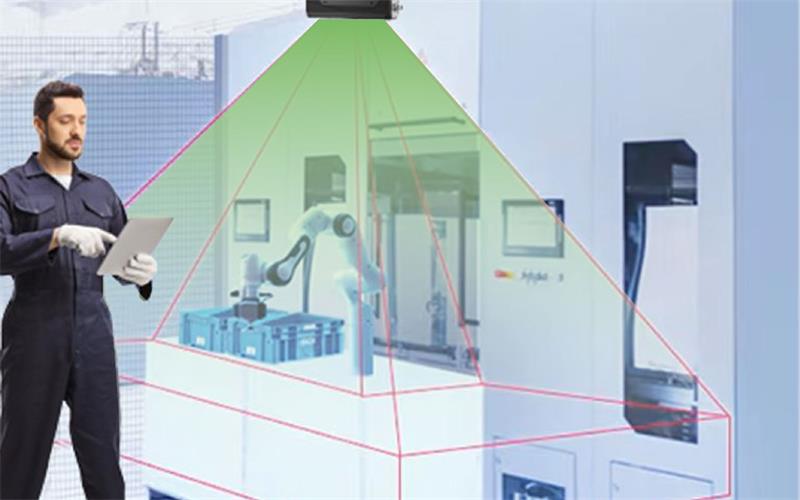

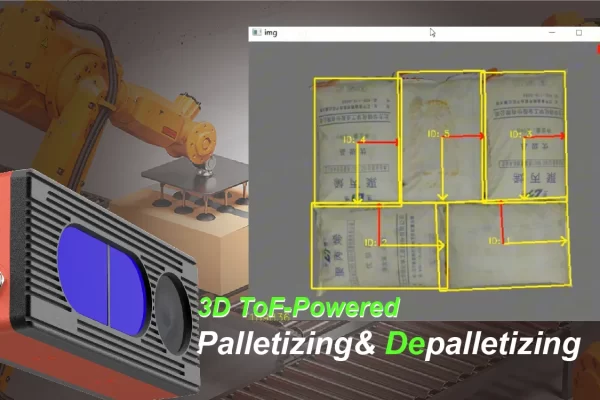

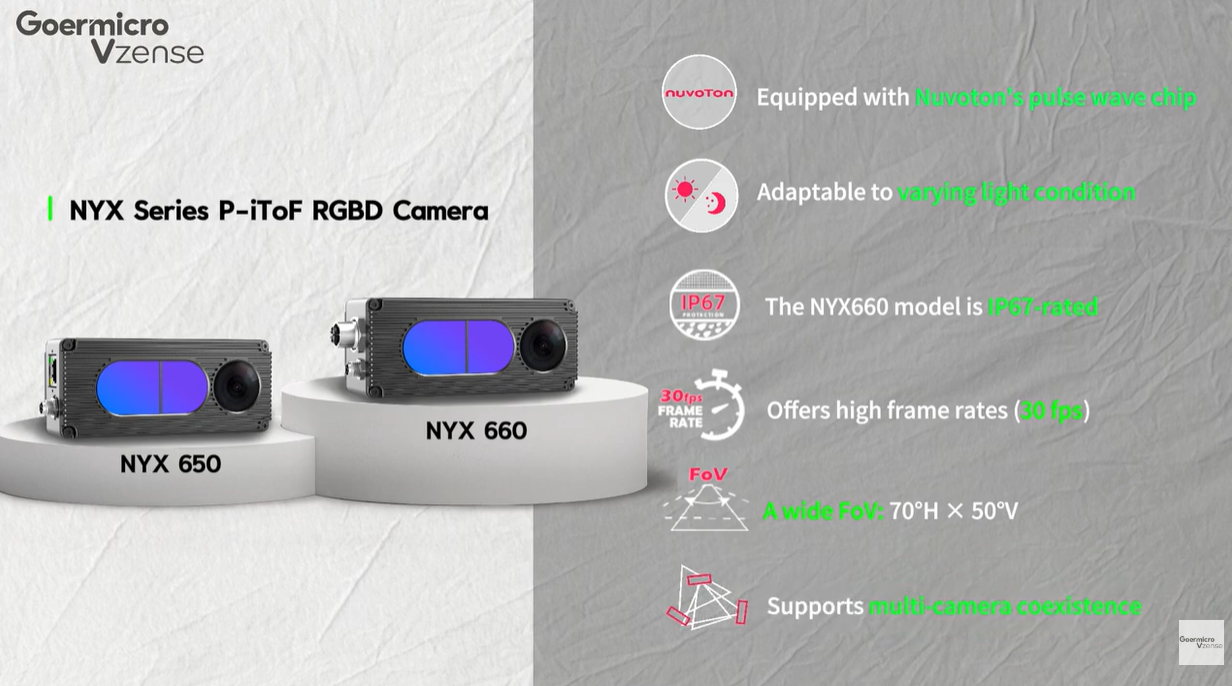

To address these pain points, Goermicro introduces a coal flow detection solution powered by industrial-grade 3D Time-of-Flight (ToF) cameras. The NYX series, designed specifically for real-time coal flow monitoring, delivers superior performance through its core capabilities:

- High-precision measurement: Millimeter-level depth accuracy enables precise calculation of coal volume and flow rate.

- Wide field of view: Provides full coverage of conveyor belts, eliminating blind spots in monitoring.

- Robust light adaptability: Performs reliably under weak light, strong light, and heavy dust conditions.

- Multi-camera coexistence: Supports synchronized operation of multiple cameras for extended monitoring ranges.

- Industrial-grade durability: IP67-rated protection ensures resistance to dust, water, and vibration.

Working Principle

Goermicro’s ToF camera emits modulated infrared light and measures the time it takes for the reflected light to return, generating real-time 3D depth maps of the coal on the conveyor belt. Advanced algorithms analyze the surface shape of the coal layer, calculate its volume, and output instantaneous flow rate data in real time. The processed results are transmitted to the control center, enabling automated management, load balancing, and predictive maintenance.

This closed-loop process: Perception→Analysis→Optimization forms the core of intelligent coal flow monitoring.

Key Advantages

| Dimension | Advantages of Goermicro NYX Series |

| Real-time performance | Millisecond-level update rate |

| Cost Efficiency | Low maintenance and long service life |

| Robustness | Stable performance under dust, strong light , and vibration |

| Detection efficiency | Wide FoV and fast response |

| Safty | Non-contact and radiation-free |

| Standardization | Dara-driven with consistent accuracy |

Conclusion

As mining continues to advance toward intelligence and automation, ToF-based coal flow detection is transforming the way coal transportation and scheduling are managed. With its high precision, superior robustness, and non-contact design, the Goermicro 3D ToF camera provides real-time insights, enhances operational efficiency, and strengthens safety — driving the comprehensive upgrade of smart mining systems.