With the rapid globalization of supply chains and the scaling up of transportation and warehousing, automation has become an urgent need. Among all the key processes, palletizing and depalletizing stand at the very core of efficient and safe material handling.

Table of Contents

1. What is Palletizing & Depalletizing?

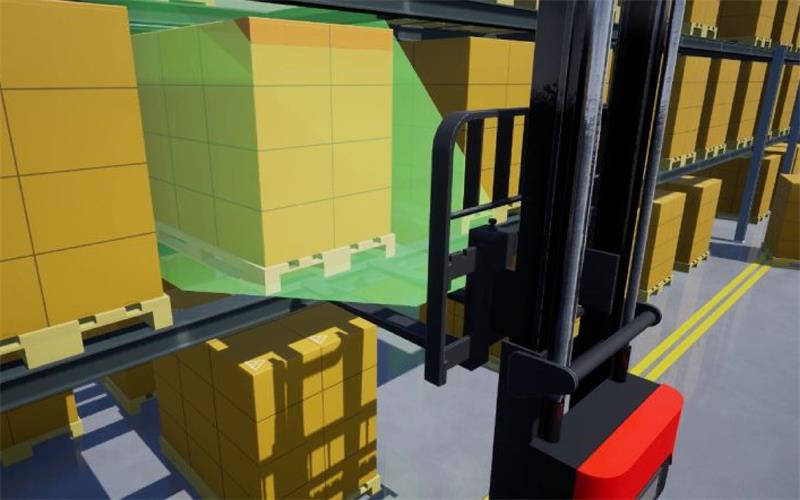

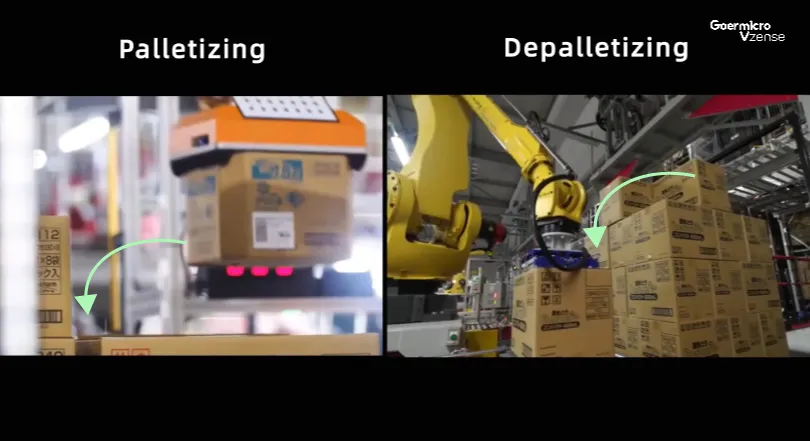

While often referred to as a single process, “palletizing & depalletizing” actually consists of two distinct tasks:

- Palletizing: The process of stacking loose items into an organized, complete pallet.

- Depalletizing: The reverse—unloading items from a pallet into individual units.

Compared to palletizing, depalletizing is much more challenging. In real-world logistics operations, robots must deal with:

- Objects of various sizes and shapes,

- Severe occlusions,

- Misaligned or shifted goods,

- External lighting or reflective interference.

These challenges make depalletizing one of the toughest automation tasks in modern logistics.

2. Visual Solutions for Automated Palletizing & Depalletizing

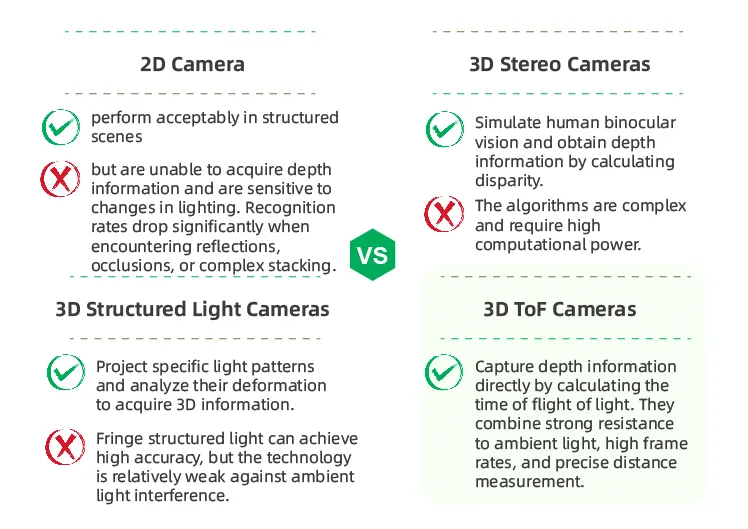

The “eyes” of automation lie in its vision system. Several approaches are currently used:

2D Cameras

Effective in structured environments but limited in handling depth, occlusions, and irregular objects.

Stereo Vision

Simulates human eyes to perceive depth. While cost-efficient, its accuracy decreases in large-scale or long-distance scenes, and it is sensitive to lighting conditions.

Structured Light

Provides high precision for static and small-range applications. However, it struggles under outdoor lighting, reflective surfaces, or dynamic scenes.

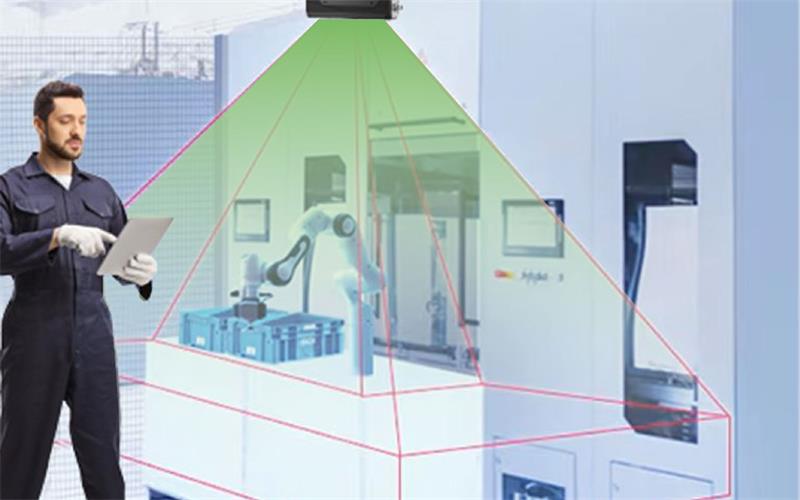

3D ToF Cameras

Time-of-Flight (ToF) cameras measure distance using light pulses, delivering robust performance in complex environments. With strong anti-light interference, adaptability to dynamic scenes, and high accuracy for irregular objects, 3D ToF cameras have become the optimal choice for palletizing and depalletizing automation.

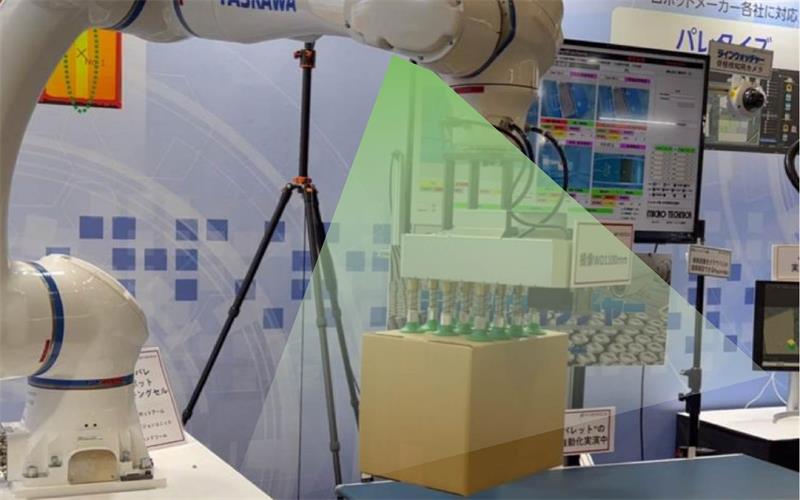

3. Why Goermicro’s 3D ToF RGB-D Cameras?

As a leading innovator in 3D perception technology, Goermicro’s 3D ToF RGB-D cameras stand out in industrial applications thanks to:

- Strong anti-light capability: Reliable in outdoor and complex lighting environments.

- Industrial-grade robustness: Stable and durable for long-term, high-intensity operations.

- Precise handling of irregular packages: Easily adapts to various non-standard goods.

These advantages make Goermicro’s solution a powerful “visual hub” for automated logistics, warehousing, and manufacturing.

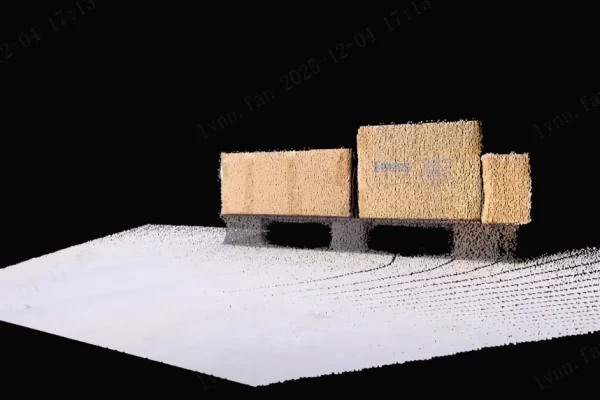

4. Smarter Depalletizing with Algorithms

Hardware alone is not enough—intelligent algorithms are essential. Goermicro’s proprietary depalletizing algorithm enables:

- Fast identification of stacked objects in complex scenes,

- Intelligent planning of the optimal grasping path,

- Significant improvements in efficiency and safety.

By combining 3D ToF cameras with smart algorithms, depalletizing robots can achieve real intelligence.

5. Looking Ahead: Automation that Frees People from Heavy Labor

The ultimate mission of automation is to free people from repetitive, high-intensity, and hazardous tasks. With continuous advancements in 3D ToF technology, the future of logistics automation will be smarter, safer, and more efficient.

👉 Want to see how it works in real life? Watch the video below to experience Goermicro’s 3D ToF depalletizing solution in action.

Conclusion:

Goermicro is committed to driving industrial automation forward with cutting-edge 3D vision solutions. Stay tuned for more insights into the future of ToF technology and its applications across industries.