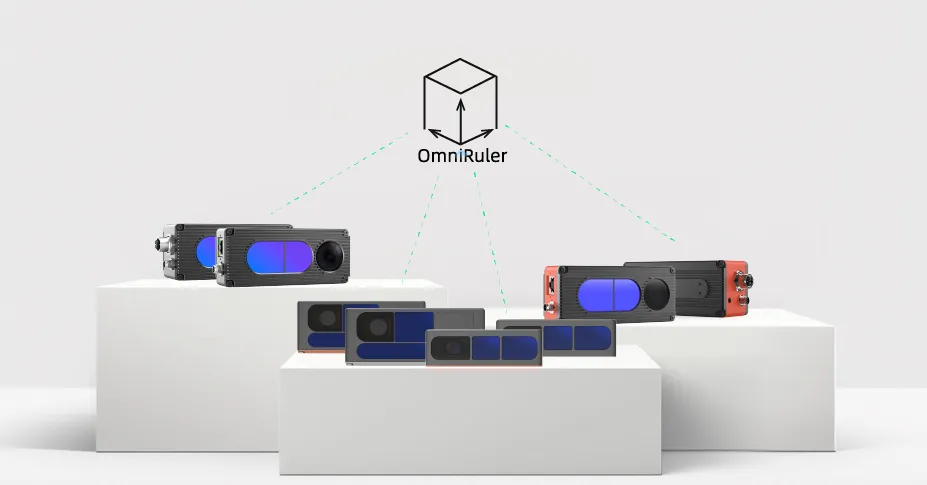

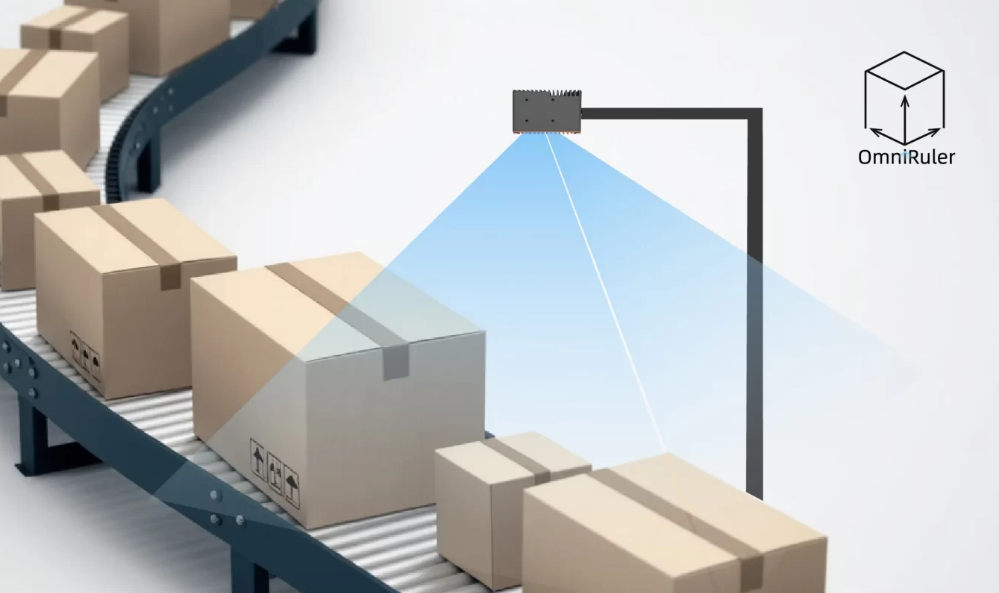

In fields such as industrial automation and logistics, accurate volume measurement is a key link affecting everything from inventory management to transportation efficiency. Traditional measurement methods often have shortcomings in terms of speed, accuracy, or adaptability to irregularly shaped objects. Time-of-Flight (ToF) cameras, especially Vzense’s OmniRuler solution, are playing a significant role in this field.

Table of Contents

The Role of Time-of-Flight Cameras in Modern Volume Measurement

Volume measurement may seem simple, but it becomes complicated when dealing with a wide variety of items – from small packages to large irregular goods. 3D cameras, especially time-of-flight systems, are changing this situation by capturing detailed depth data that traditional 2D cameras or laser scanners cannot match. Vzense’s OmniRuler solution, specifically designed for volume measurement, overcomes many common challenges with indirect Time-of-Flight (iToF) technology. Unlike methods that require multiple sensors or slow scanning, this 3D camera-based solution can capture complete 3D point cloud data of objects in real-time, enabling accurate volume calculation even for items with uneven surfaces or complex geometries.

How iToF Technology Helps OmniRuler Improve Efficiency

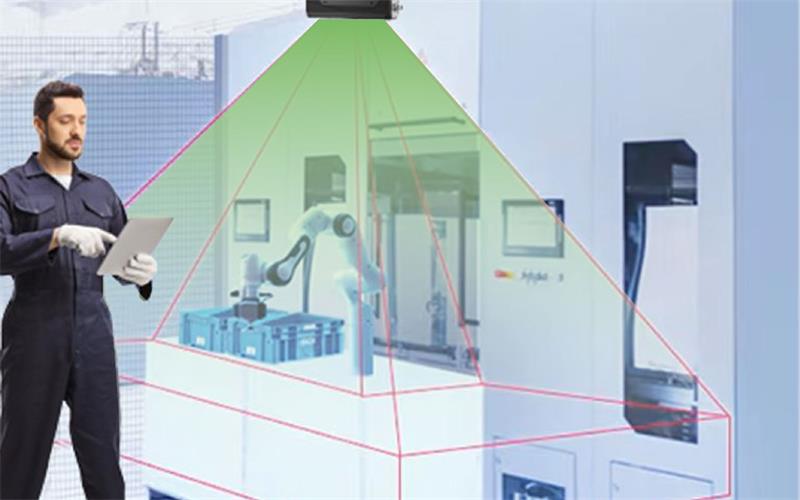

At the core of OmniRuler’s performance is iToF technology, which works by emitting modulated light signals and measuring the time it takes for the light signals to reflect off an object and return to the sensor. This data is processed to generate a detailed depth map, laying the foundation for accurate volume calculation.

A standout advantage of this method is speed. Traditional volume measurement tools may take seconds or even minutes to measure complex objects, while time-of-flight cameras can complete scanning in an extremely short time. OmniRuler further shortens this time on this basis, requiring only one second to obtain the length, width, and height data of the target object. In high-throughput environments such as warehouses, this speed is crucial for maintaining operational efficiency.

Key Advantages of 3D Cameras in Volume Measurement

Time-of-flight cameras bring multiple advantages to volume measurement, making them ideal for industrial scenarios:

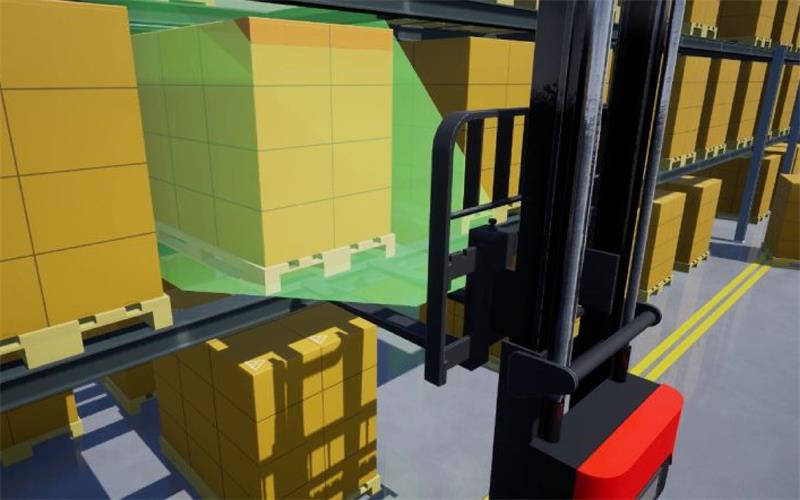

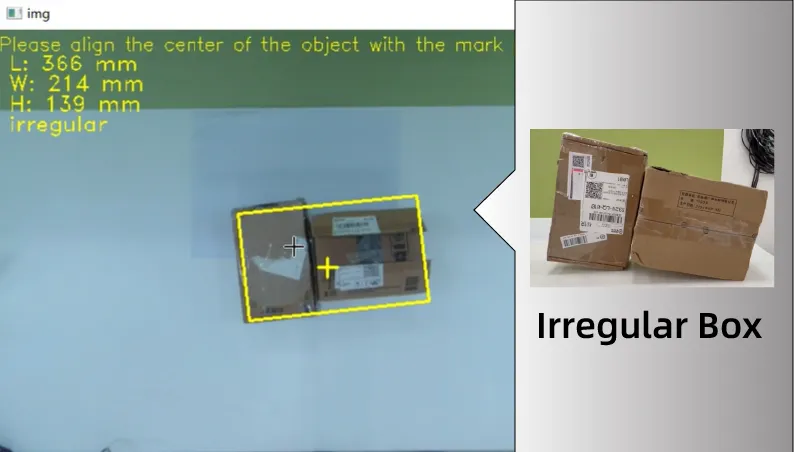

- High precision across object types: Whether measuring boxes, bags, or irregularly shaped components, 3D cameras can capture every contour, ensuring the accuracy of volume calculation (as shown in the figure below).

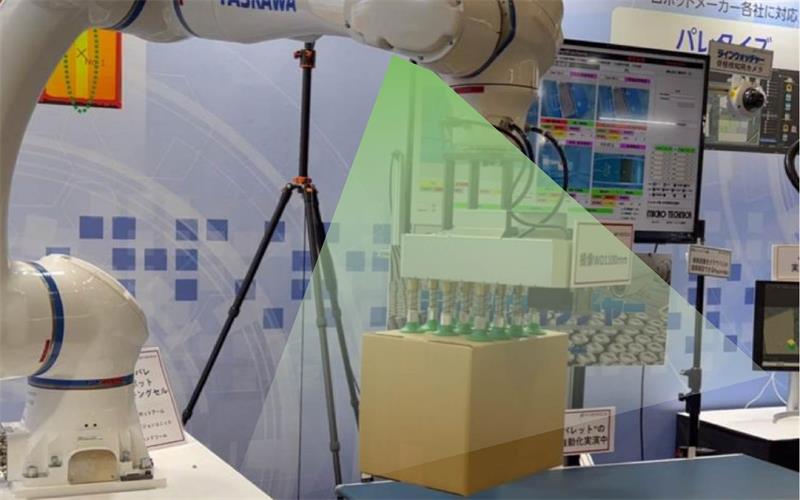

- Real-time processing capability: iToF technology supports instant data collection and analysis, which is crucial for integration into AGV/AMR systems or conveyors in fast-paced logistics scenarios.

- Stable performance in complex environments: Unlike some sensors that degrade in performance under changing light or reflective surfaces, ToF cameras maintain stable reliability and are suitable for diverse industrial environments.

Practical Applications of Time-of-Flight Cameras in Volume Measurement

In practical applications such as e-commerce warehousing and smart logistics, OmniRuler quickly acquires cargo volume data through time-of-flight cameras, greatly improving operational efficiency and management accuracy, and bringing significant changes to the industry.

The versatility of time-of-flight cameras in volume measurement has been demonstrated in multiple industries. Here are some key scenarios where OmniRuler excels:

- Logistics and transportation: Express companies and warehouses use 3D cameras to quickly measure package volumes, optimize packaging, determine accurate transportation costs, reduce human errors, and speed up sorting processes.

- Manufacturing: In production lines, volume measurement helps ensure that components meet specifications. ToF technology can inspect components during assembly, detecting problems before deviations affect the final product.

- Inventory management: With 3D cameras, the volume measurement and recording of stacked or stored items can be done without contact, reducing interference with normal operations and making inventory tracking more efficient.

Why OmniRuler Stands Out Among 3D Camera Solutions

Vzense’s OmniRuler is not an ordinary volume measurement tool but a solution designed specifically for industrial needs. By combining iToF technology with advanced algorithms, it has the following advantages:

- One-second measurement speed: This fast processing capability ensures that it can be seamlessly integrated into high-speed production lines or transportation lines.

- Wide measurement range: From small objects to large pallets, the system maintains measurement accuracy across different sizes.

- Easy integration: Compatible with existing industrial automation systems (including AGVs and robots), minimizing setup time and costs.

To learn more about how 3D cameras are transforming industrial processes, check out our previous articles.

Future Trends: Innovation in Time-of-Flight Technology and Volume Measurement

With the development of industrial automation, the role of time-of-flight cameras in volume measurement is bound to expand further. Emerging trends include better integration with artificial intelligence to achieve predictive volume analysis, and enhanced compatibility with autonomous robots to realize fully automated inventory management.

In conclusion, time-of-flight cameras are redefining the possibilities of volume measurement. With solutions like OmniRuler, enterprises can obtain the speed, accuracy, and flexibility needed to succeed in today’s fast-paced industrial environment. Whether in logistics, manufacturing, or warehousing, adopting 3D camera technology may be the key to improving efficiency.