In modern manufacturing and logistics environments, industrial automation is evolving at a rapid pace. Among the most complex tasks are depalletizing and palletizing —where robots must recognize, grasp, and move objects from cluttered bins or neatly stacked pallets.

Now, with the integration of Time-of-Flight (ToF) 3D cameras, these demanding applications are becoming significantly more intelligent, efficient, and accurate.

Table of Contents

How ToF Cameras Enhance Industrial Automation?

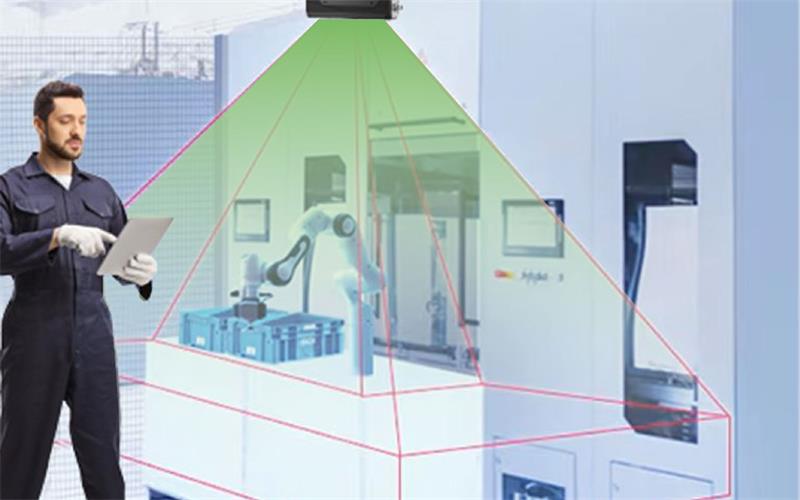

Time-of-Flight cameras work by measuring the time it takes for infrared light emitted from the camera to bounce off an object and return. This allows them to capture highly accurate depth data. Compared to traditional 2D vision systems, ToF technology provides complete three-dimensional spatial information, dramatically improving the performance and reliability of industrial robots in depalletizing and object picking tasks.

In scenarios with irregularly shaped or randomly stacked items, indirect Time-of-Flight (iToF) cameras offer exceptional environmental adaptability and superior depth sensing capabilities. As the point cloud shown below, Vzense’s DS series ToF cameras excel in precise edge detection.

Key Challenges in Depalletizing and Palletizing

Before the introduction of 3D camera systems, industries faced several significant issues:

❌ Heavy reliance on manual labor: Tasks were repetitive, inefficient, and posed safety risks.

❌ Limitations of 2D vision systems: Lacking depth data, these systems often resulted in high failure rates during object grasping.

❌ Rigid automation setups: Systems lacked adaptability when object shapes or arrangements changed.

These issues hindered the scalability and flexibility of industrial automation in real-world production environments.

How Vzense 3D ToF Cameras Enable Flexible Automation?

To address these pain points, Vzense’s RGB-D ToF cameras combine high-precision depth data with high-resolution RGB imaging. When integrated with intelligent algorithms and robotic control systems, they deliver the following capabilities:

✅ High-accuracy 3D object recognition: Enables fast localization of object shape, size, and position.

✅ Real-time path planning and obstacle avoidance: Robots can intelligently avoid collisions and optimize their grasping paths.

✅ Adaptability to mixed or disordered stacking: Objects of various shapes, sizes, and materials can be accurately identified.

✅ Increased production line stability: Suitable for dynamic industrial environments with changing workloads.

Real-World Application: Smart Depalletizing Powered by 3D Cameras

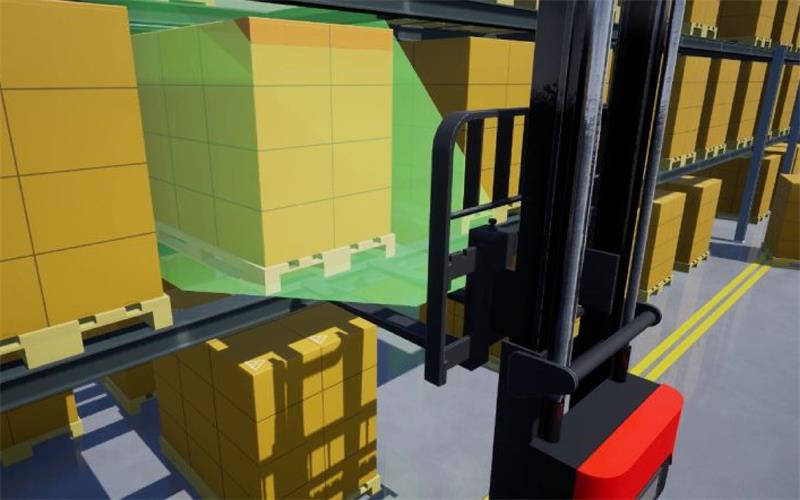

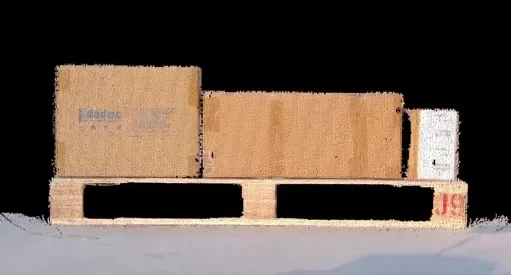

In a project with a major electronics manufacturer, Vzense ToF cameras was integrated into an automated depalletizing workstation. Faced with cartons of varying sizes, uneven stacks, and reflective surfaces, the system used depth maps to determine precise object locations and guide robotic arms for accurate grasping.

The image below illustrates the camera’s robust detection of wooden pallets in real time.

By using vzense’s solutions, manual intervention was reduced by 80%, enabling around-the-clock unattended operation. This translated into lower labor costs, greater operational efficiency, and improved adaptability for flexible production lines.

Why Partner with Vzense for 3D Vision Solutions?

Vzense is committed to delivering customizable RGB-D ToF camera solutions for industrial clients. Whether you’re tackling high-speed object picking, complex depalletizing, or intelligent sorting tasks, Vzense provides reliable, precise, and economical 3D vision support.

Shaping the Future of Smart Factories with Time-of-Flight Technology

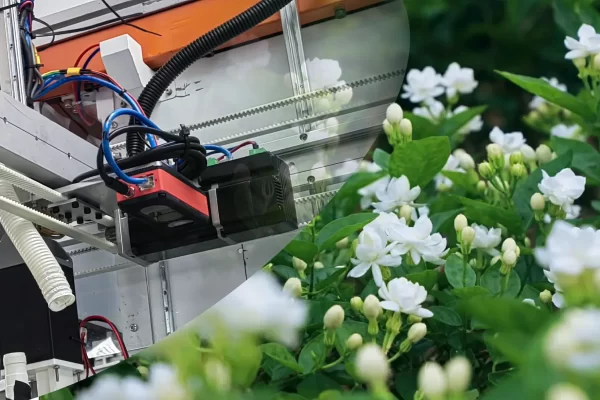

From automated depalletizing to flexible bin picking, Time-of-Flight-based 3D vision systems are becoming a core enabler of next-generation industrial automation. With Vzense’s high-performance RGB-D ToF cameras, factories can boost productivity, enhance system flexibility and stability, and pave the way to truly intelligent manufacturing.

Want to explore more 3D camera applications? Check out our case study blogs.

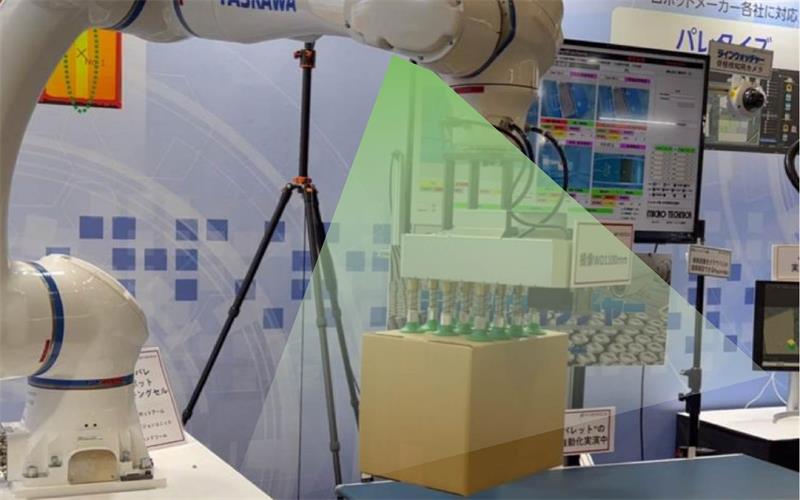

Vzense will be showcasing its latest industrial 3D vision solutions at the 2025 Image Sensing Show in Yokohama, Japan. We warmly welcome you to visit our booth and experience firsthand the power of ToF technology in industrial automation.