Table of Contents

Temperature guidelines for camera use and storage

The operating temperature range for the Vzense 3D ToF camera is -20°C to 50°C, and the storage temperature range is -30°C to 70°C. During use, be mindful of the working environment temperature and storage conditions. It is advised not to exceed the temperature limits specified for the product. If the operating environment is too cold, preheat the camera for a few minutes before use, otherwise, imaging performance may be affected.

How to install the Vzense 3D ToF camera?

For proper installation and related precautions, please refer to the application note “How to install Vzense 3D Time of Flight (ToF) camera correctly”.

Using the Vzense 3D ToF camera in High-Temperature environments

The Vzense 3D ToF camera utilizes a passive cooling design, with its metal casing serving as a heat-dissipation mechanism. During operation, heat generated by the internal working unit is quickly transferred to the metal casing and then dispersed into the surrounding environment. Therefore, it is normal to feel the casing slightly hot to the touch after the camera has been in use for some time.

The Vzense 3D ToF camera is equipped with an overheating protection feature. If the internal working unit’s temperature becomes excessively high during operation, the camera will activate a self-protection mechanism and automatically shut down.

When operating the camera in high-temperature environments, measures can be taken to reduce heat generation or improve heat dissipation efficiency.

Measures to reduce camera heat generation

1. Lower frame rate

The higher the frame rate during camera operation, the greater the workload and heat generation. To reduce power consumption, it is possible to lower the frame rate, provided the usage scenario requirements are met.

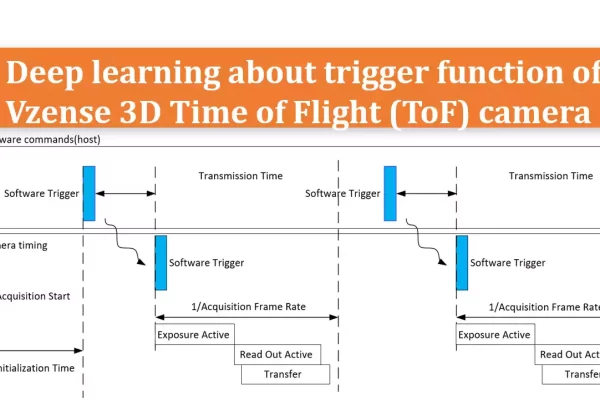

2. Use trigger modes

The Vzense 3D ToF camera offers three working modes: Active Mode, Hardware Trigger Mode, and Software Trigger Mode.

In Active Mode, the camera operates continuously under a high workload, leading to significant heat generation.

In Trigger Modes (either Hardware or Software Trigger Mode), the camera only captures and processes an image when a trigger command is received. This allows a substantial reduction in operating frequency, thus lowering power consumption and minimizing heat generation.

Improving camera heat dissipation efficiency

1. Use thermal grease

Filling the contact surface between the camera and its mounting bracket with thermal grease can significantly improve the camera’s heat dissipation efficiency. There are inevitable gaps between the camera and its mounting bracket, and the air within these gaps can hinder the transfer of heat from the camera to the bracket. The mechanism of thermal grease lies in filling these gaps between the heat source and the heat sink, achieving full contact between the two, optimizing thermal transfer efficiency, and facilitating rapid heat dissipation. Applying thermal grease between the camera and the mounting bracket can meet the heat dissipation needs of most high-temperature environments.

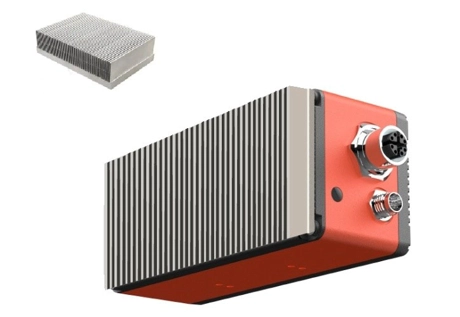

2. Add additional heat sinks

If filling the contact surface with thermal grease alone does not meet the camera’s heat dissipation requirements, you can further improve the cooling performance by attaching heat sinks to the camera body. In most cases, the camera mounting brackets are made of steel, while heat sinks are typically made of aluminum alloy. The thermal conductivity of aluminum is more than four times that of steel (the thermal conductivity of steel is 58.2 W/(m·K), while that of aluminum is 237 W/(m·K)). The structural design of heat sinks significantly increases the surface area for heat dissipation, thereby enhancing cooling efficiency, as illustrated in the diagram below:

When applying heat sinks, the surface for applying heat sinks can be freely selected based on the actual installation conditions of the camera. However, it is essential to fill the space between the camera and the heat sink with thermal grease to minimize gaps and ensure the heat sink functions effectively.

3. Add cooling fans

In extremely high-temperature environments, cooling fans can be added on top of the heat sinks. This accelerates air circulation and further enhances heat dissipation efficiency, as illustrated in the diagram below:

Using the Vzense 3D ToF camera in Low-Temperature environments

If the ambient temperature is too low, the camera may fail to start due to the cold. In such cases, measures can be taken to gently warm the camera (e.g., using a heat gun or heating plate) to assist in starting it. Once the camera has started, it can operate normally by relying on the heat it generates during operation.