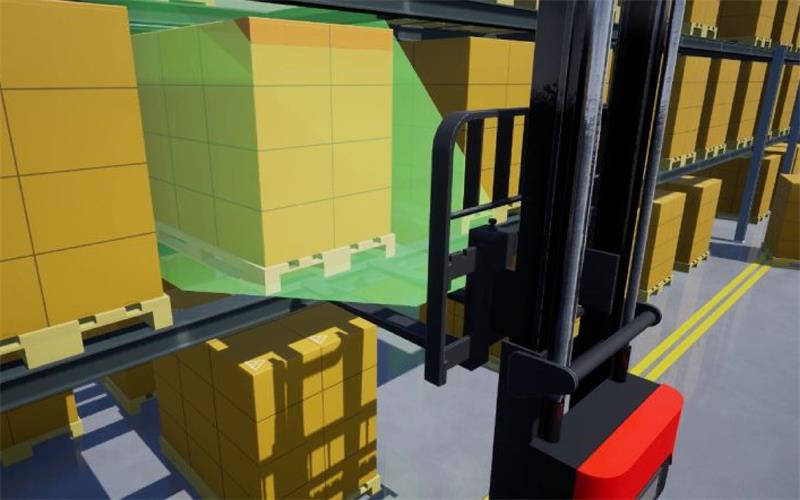

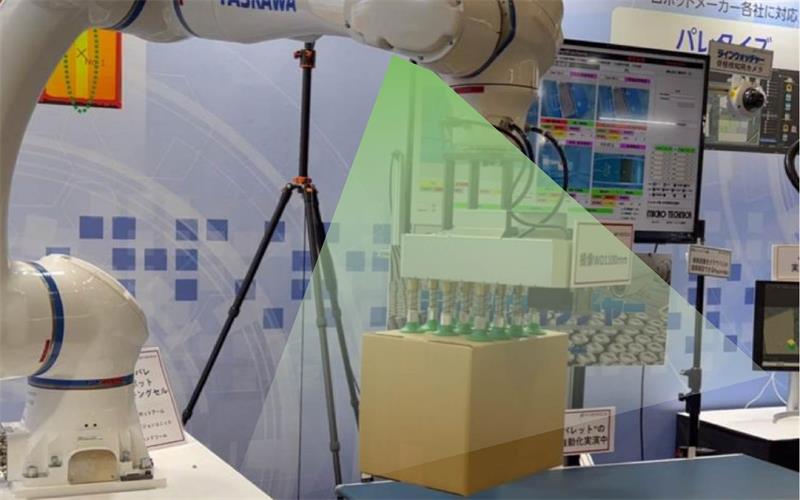

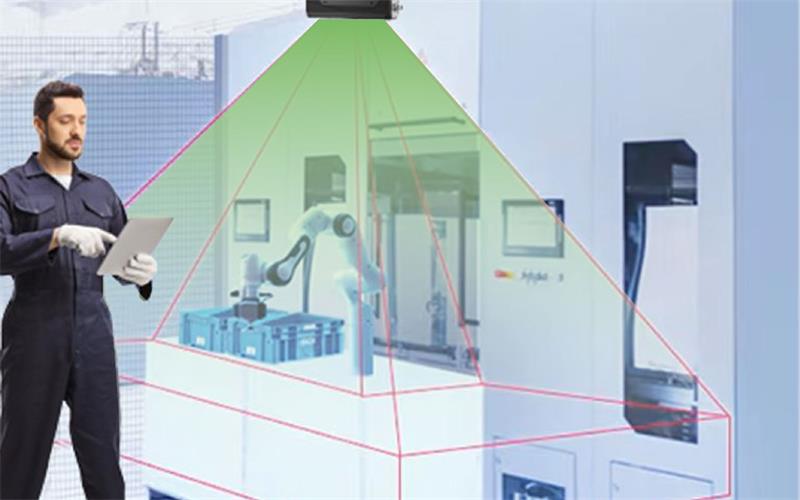

With the development of technology, 3D ToF camera has been widely used in the field of automatic pallet identification of various AGVs and automatic forklifts. 3D time of flight camera has the characteristics of high cost performance, better real-time performance, low system computing power requirements, and suitable for scene capture in moving. 3D Time of Flight (ToF) cameras can capture images of pallets, combine them with corresponding image processing algorithms to identify the pallets of forklift goods, and obtain its position and posture coordinates, intelligently adjusting the forklift direction to achieve unmanned intelligent pallet transportation, thereby solving the problem of significant pallet position deviation angles during forklift docking.

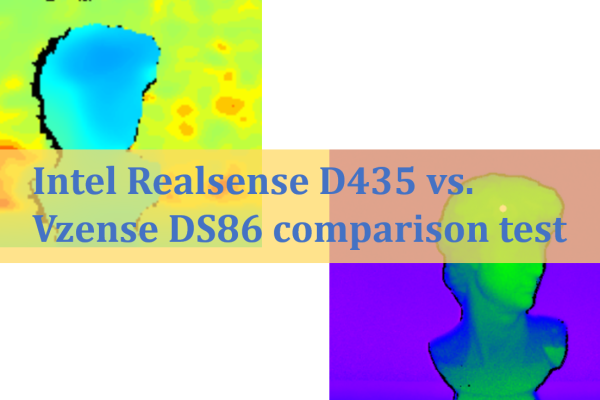

In practical application scenarios, pallet materials and colors vary greatly, and different materials and colors can have a significant impact on the imaging performance of ToF cameras. In order to facilitate customers to understand these effects more intuitively, we have selected several common and representative pallet types, such as black plastic pallets, blue plastic pallets, wooden pallets, and galvanized metal pallets. We choose the NYX series cameras, which are based on the Pulse indirect Time of Flight(P-iToF) working principle and have a wide dynamic range. We tested and recorded the imaging performance of the NYX series ToF cameras combined with different ambient light scenes indoor and outdoor.

Table of Contents

NYX series products

The Vzense NYX series includes two products, the NYX650 and NYX660, which are based on P-iToF technology. These cameras feature a high SNR, strong light resistance, width dynamic range, prevention of range alising, and adaptive multi-camera coexistence. Its P-iToF technology paired with global shutter exposure lenses makes it easier to capture fast-moving objects’ trajectories. Its pulse iToF technology paired with global shutter exposure lenses makes it easier to capture fast-moving objects‘ trajectories, providing stronger light resistance outdoors and better adaptability to outdoor scenes. The cameras are designed to industrial grade standards, ensuring high reliability and stability. The bidirectional mounting hole design facilitates structural integration and fixation. The optional waterproof design with an aviation plug supports a high protection level of IP67.

Testing conditions

Target object: Black plastic pallet, blue plastic pallet, wooden pallet, galvanized metal pallet.

Camera testing: Randomly select 1 calibrated NYX650 cameras. During calibration, use an 80cm x 80cm gray calibration board with 40% planar reflectance. The imaging performance of the NYX660 is identical to that of the NYX650, so the performance of the NYX650 can represent that of the NYX660.

Camera position: The camera is mounted on a height of 305mm and placed on the ground. As shown in the figure below:

Camera settings: Default settings, camera preheated for 20 minutes.

Imaging environment:

1. Indoor, ambient temperature 22°C, light intensity is about 200Lux.

2. Outdoor, ambient temperature 22°C, light intensity is about 64000Lux.

Testing data of pallet identification

Black plastic pallet

Types of saved data and images: RGB image, point cloud image.

Testing target: Black plastic pallet.

Testing ambient:

1. Indoor lighting, approximately 200lux, with a distance of 1 meter from the camera.

2. Outdoor lighting, approximately 64000lux, with a distance of 2 meters from the camera.

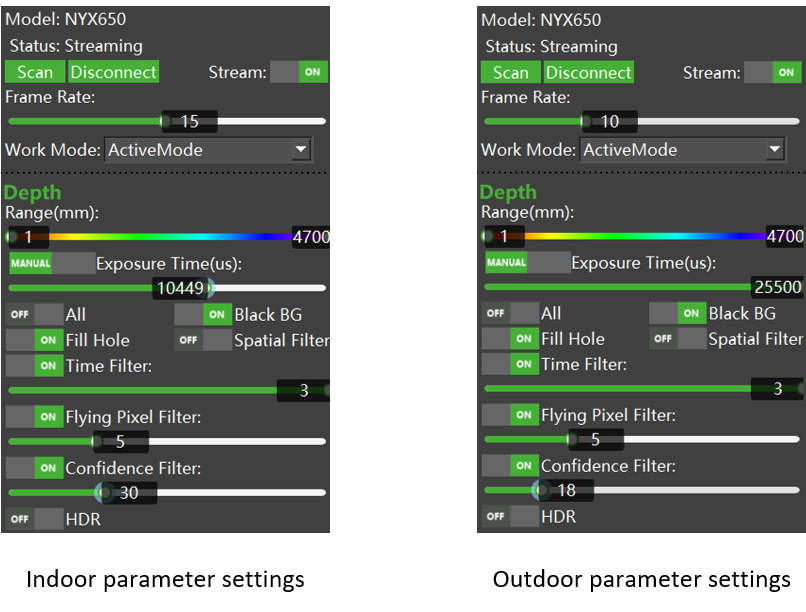

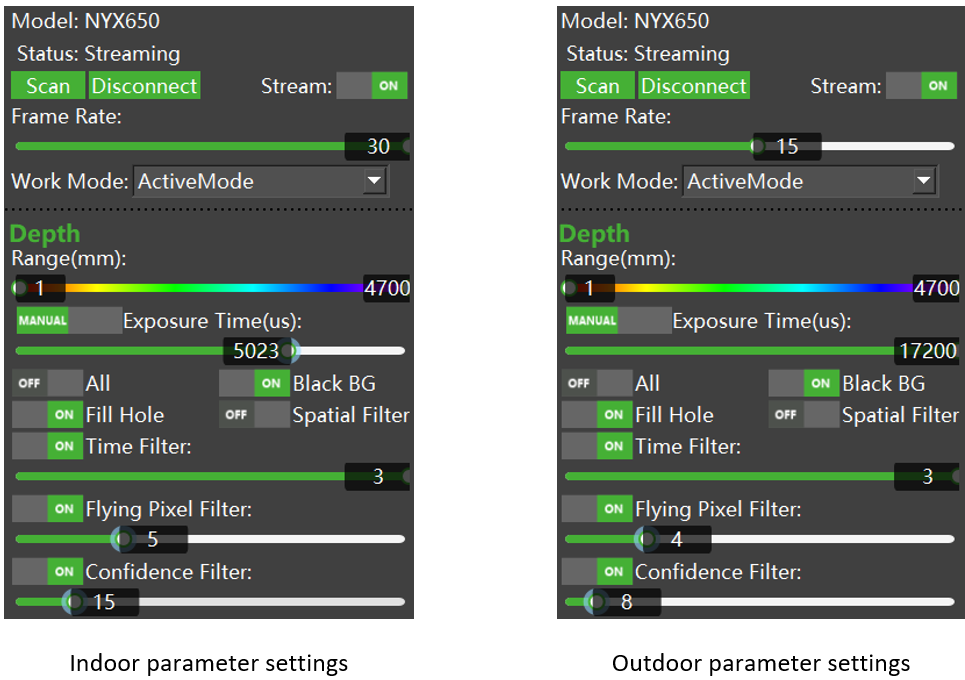

Camera parameter setting: As shown in the figure below:

Parameter settings instructions:

Exposure time: Black objects have low reflectivity, which can lead to insufficient light intensity reflected back to the ToF lens, resulting in ineffective imaging. By increasing the exposure time, the intensity of the reflected light from black objects can be improved, thereby enhancing their imaging quality.

Confidence filter threshold: The low reflectivity of black objects can result in a low signal-to-noise ratio, making it difficult to measure the object’s distance.

Test images and results at different distances

1) Testing at a Distance of 1m from the target object indoor, the RGB image and point cloud image are shown below:

2) Testing at a Distance of 2m from the target object outdoor, the RGB image and point cloud image are shown below:

Blue plastic pallet

Types of saved data and images: RGB image, point cloud image.

Testing target: Blue plastic pallet.

Testing ambient:

1. Indoor lighting, approximately 200lux, with a distance of 1 meters from the camera.

2. Outdoor lighting, approximately 64000lux, with a distance of 2 meters from the camera.

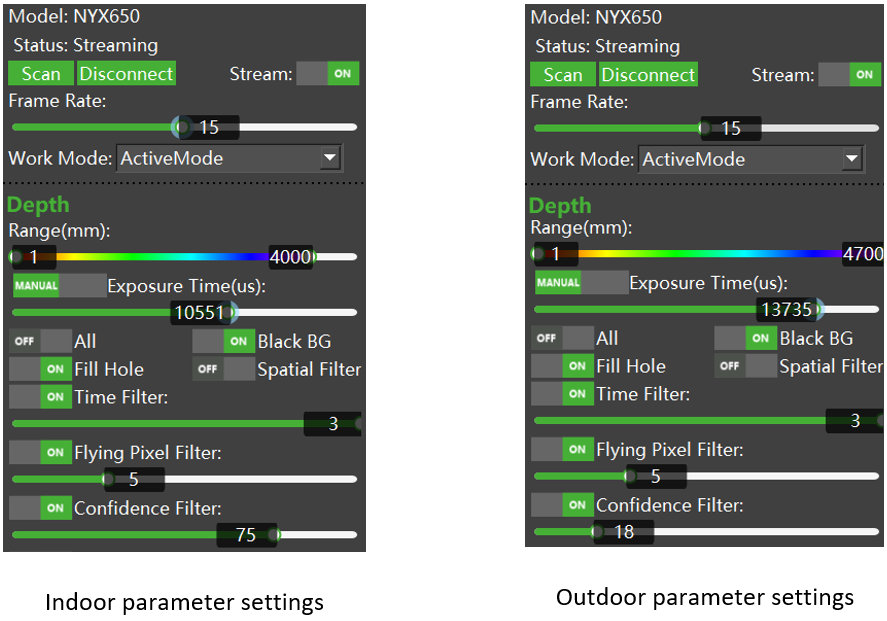

Camera parameter setting: As shown in the figure below:

Parameter settings instructions:

Generally, the reflectance of blue, yellow, green and other color objects are more suitable for the working range of the ToF camera. Users can use the default camera parameters or adjust the exposure time and filtering parameters according to actual conditions. When making adjustments, users can observe the point cloud image and select the parameters they find most satisfactory.

Test images and results at different distances

1) Testing at a distance of 1m from the target object indoor, the RGB image and point cloud image are shown below:

2) Testing at a distance of 2m from the target object outdoor, the RGB image and point cloud image are shown below:

Wooden pallet

Types of saved data and images: RGB image, point cloud image.

Testing target: Wooden pallet.

Testing ambient:

1. Indoor lighting, approximately 200 lux, with a distance of 1 meters from the camera.

2. Outdoor lighting, approximately 64000 lux, with a distance of 2 and 3 meters from the camera.

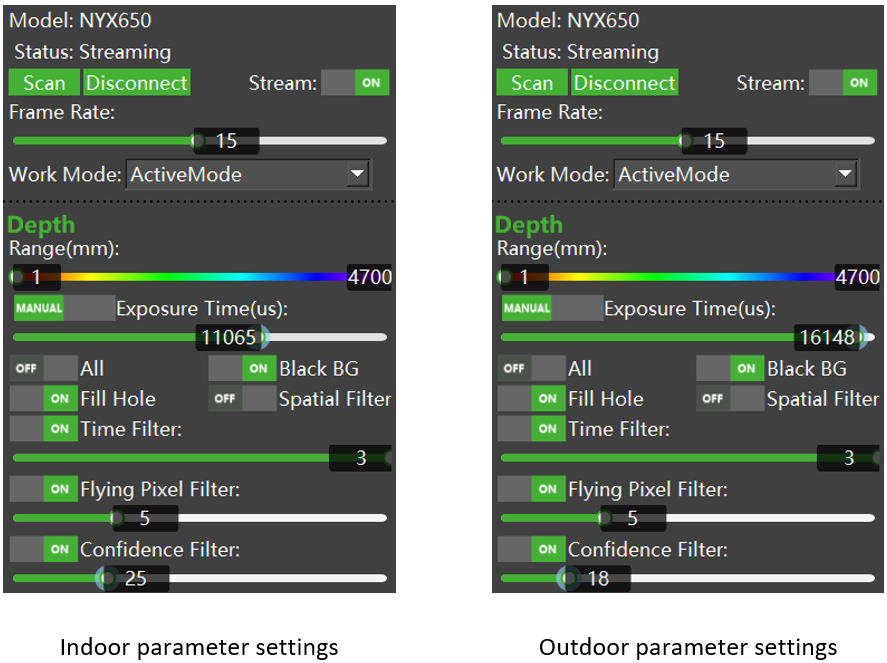

Camera parameter setting: As shown in the figure below:

Parameter settings instructions:

The reflectivity of wooden pallets falls within the suitable working range of the ToF camera. Users can use the default camera parameters or adjust the exposure time and filtering parameters according to actual conditions. When making adjustments, users can observe the point cloud image and select the parameters they find most satisfactory.

Test images and results at different distances

1) Testing at a distance of 1m from the target object indoor, the RGB image and point cloud image are shown below:

2) Testing at a distance of 2m from the target object outdoor, the RGB image and point cloud image are shown below:

3) Testing at a distance of 3m from the target object outdoor, the RGB image and point cloud image are shown below:

Galvanized metal pallet

Types of saved data and images: RGB image, point cloud image.

Testing target: Galvanized metal pallet.

Testing ambient:

1. Indoor lighting, approximately 200lux, with a distance of 1 meters from the camera.

2. Outdoor lighting, approximately 64000lux, with a distance of 2 and 3 meters from the camera.

Camera parameter setting: As shown in the figure below:

Parameter settings instructions:

The surface of the galvanized metal pallet has a high reflectivity, which is similar to the mirror reflection effect. When the light of the ToF camera shines on the surface of the tray, the reflection light is strong in the part opposite the camera. Therefore, when setting parameters, the exposure time should not be too long. Due to the large incident angle, other areas tend to reflect light far away, causing insufficient light intensity received by the camera and ineffective imaging. Reducing the threshold of confidence filter and flying pixel filter can obtain more effective point clouds.

Test images and results at different distances

1) Testing at a distance of 1m from the target object indoor, the RGB image and point cloud image are shown below:

2) Testing at a distance of 2m from the target object outdoor, the RGB image and point cloud image are shown below:

3) Testing at a distance of 3m from the target object outdoor, the RGB image and point cloud image are shown below: