Table of Contents

Overview of ToF Camera Applications in Mining

As the mining industry faces increasingly complex operational environments and growing demands for automation, Time-of-Flight (ToF) cameras are emerging as critical sensing technologies due to their exceptional 3D depth sensing capabilities. As early as 2015, there is an experimental study explored the use of 3D ToF cameras in equipment for detecting remote cave systems. Research shows that ToF technology offers significant advantages over 3D laser scanners in terms of data acquisition speed and volume during mine site surveys.

Why Does the Mining Industry Need ToF Cameras?

Mining operations typically confront three major challenges: dust-heavy environments, complex lighting conditions, and harsh workspaces; the need for rapid, precise measurements and decision-making; and the demand for scalable automation.

ToF cameras excel in both high-intensity and low-light environments, reliably operating in challenging aboveground and underground conditions. Their compact design and flexible deployment make them ideal for integration into autonomous robots (AGV/AMR), fixed monitoring stations, and other platforms, driving the advancement of intelligent mining operations.

Applications of ToF Cameras in Mining

1. 3D Mine Modeling and Spatial Mapping

ToF cameras enable real-time scanning of mine tunnels and workspaces to generate high-precision 3D models. These models support ventilation system design, equipment layout optimization, and structural safety inspections. By accurately tracking changes in mine structures, ToF technology enhances underground mapping efficiency and operational safety, serving as a cornerstone tool for digital twin mine modeling.

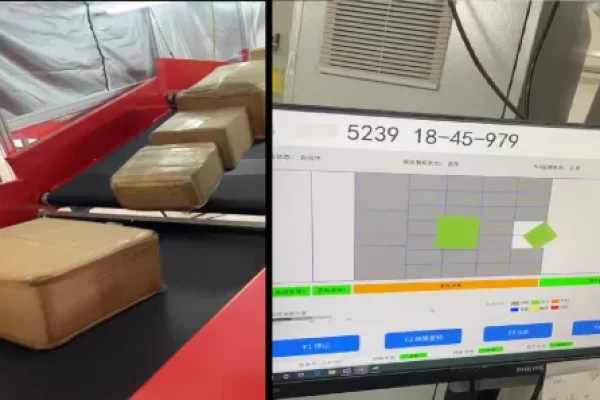

2. Ore Volume Measurement and Conveyor Belt Monitoring

During ore transportation, ToF cameras perform non-contact, real-time volumetric analysis of materials on conveyor belts, improving measurement accuracy and control capabilities. Collected data seamlessly integrates with Mining Execution Systems (MES), ensuring synchronization between information flow and logistics.

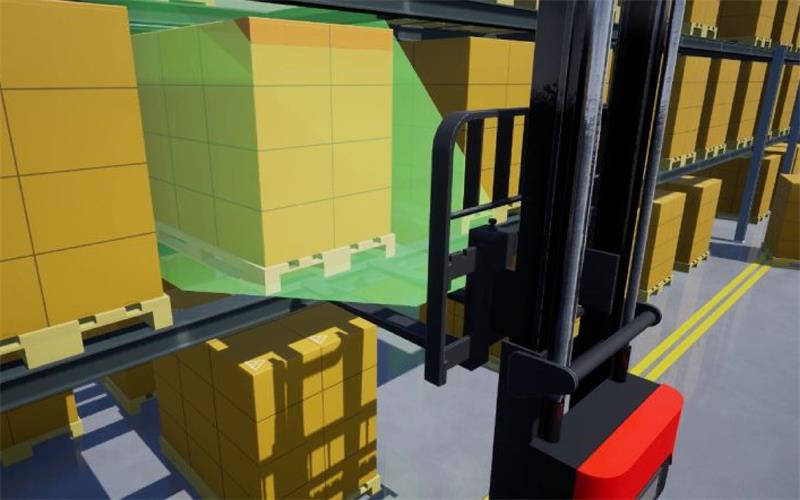

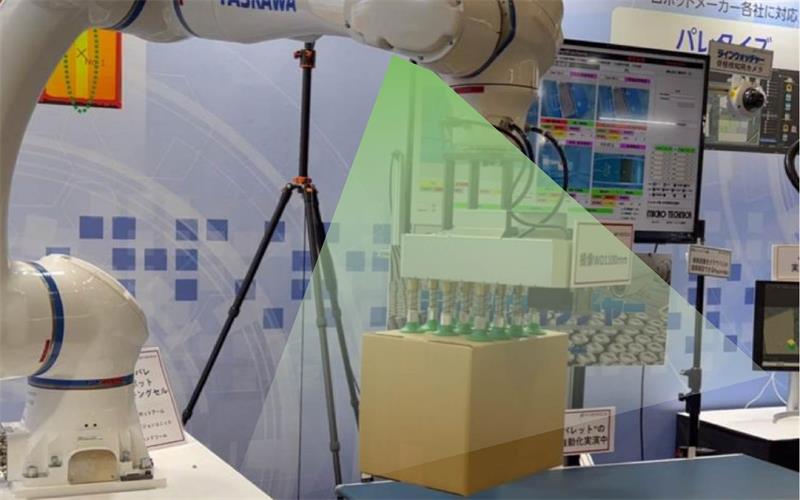

3. Obstacle Avoidance and Navigation for Autonomous Vehicles (AGV/AMR)

With superior 3D perception, ToF cameras rapidly identify obstacles and terrain changes in mining areas, providing reliable navigation and collision avoidance for AGVs and AMRs. Their high frame rates, wide field-of-view, and real-time dynamic/static obstacle detection make them particularly suited for complex, dynamic mining environments.

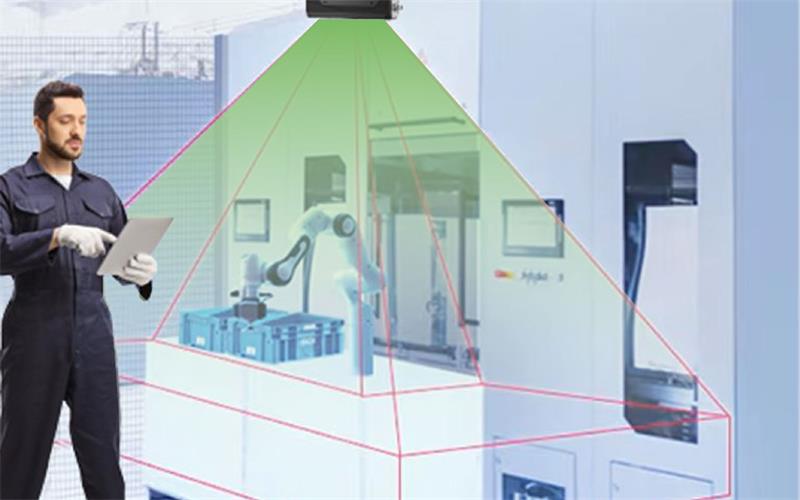

4. Underground Personnel Monitoring and Behavior Recognition

In underground settings, ToF cameras precisely track worker locations and movements, enabling AI-driven behavior recognition for fall detection, boundary alerts, and more. Synchronized RGB and depth imaging significantly improves recognition accuracy, allowing deployment in critical zones such as tunnels, entry points, and equipment areas to enhance safety management.

5. Equipment Condition Monitoring and Structural Deformation Analysis

ToF cameras also support non-contact inspection of critical mining equipment components, detecting subtle changes like bolt loosening or structural deformation without disrupting operations. The collected data enhances predictive maintenance capabilities and integrates with digital asset management systems to optimize equipment lifecycle management.

Why Choose Vzense’s ToF Solutions?

With over a decade of expertise in 3D ToF technology, Vzense delivers professional, robust, and high-performance Time-of-Flight (ToF) camera solutions for industrial clients. Key advantages include:

- 📌 Compact All-in-One Design (RGB + Depth, space-efficient integration)

- 📌 Millimeter-Level Accuracy (powered by IMX570 or Nuvoton chipsets)

- 📌 High Frame Rate + Wide FOV (dynamic environment adaptability)

- 📌 IP67 Rating + M12 Connectors (resilience in harsh mining conditions)

- 📌 Software-Hardware Synergy (compatible with mainstream operating platforms)

Future Outlook: ToF Cameras as the “Visual Core” of Smart Mines

As digital and green mining initiatives accelerate, ToF technology will play an increasingly vital role:

- Enabling real-time sensing for mine digital twin systems

- Providing environmental data for autonomous vehicles and robotics

- Integrating with AI algorithms to enable autonomous decision-making

From underground tunnel modeling to surface logistics automation, and from equipment diagnostics to behavior analytics, Time-of-Flight (ToF) cameras are becoming the visual foundation of modern mining operations.

If you are interested in vzense’s 3D ToF solutions, you can click here to learn more about the products and solutions. Or follow our LinkedIn to get more of our latest news. If you would like to explore more usage scenarios for our products you can click here to get them.