As machine vision technology continues to develop, the application of 3D cameras for object recognition and behavior recognition is becoming increasingly common. One could say that 3D cameras serve as the eyes of terminals and robots. Also known as depth cameras, 3D cameras can detect the depth of field in the captured space, which is their most significant difference from regular cameras.

There are currently three common types of depth cameras on the market:

Structured-light: Representative companies include Apple PrimeSense, Orbbec, and Mech-Mind. Structured light works by projecting active structural information onto the surface of the object being measured, such as laser stripes, Gray codes, or sinusoidal patterns. Then, one or more cameras capture the structured light image on the surface. Finally, based on the principle of triangulation, 3D reconstruction is achieved through 3D image analysis and calculation.

Stereo vision: Representative companies include Intel RealSense, Mech-Mind, and DJI.

Time-of-Flight (ToF): Representative companies include Vzense, Microsoft Kinect, Lucid, and Basler.

This article selects two products, Intel Realsense D435 and Vzense DS86, and evaluates the imaging effects of these two 3D cameras in different scenarios.

Table of Contents

Product introduction

The RealSense D435 is a 3D camera from Intel, based on stereo vision technology. It offers high-quality depth perception, with a compact design measuring 90mm × 25mm × 25mm and a measurement range of 0.3 to 3 meters. It has low hardware requirements and cost, and can work with a regular CMOS sensor. As long as the lighting is appropriate and not too dim, it is suitable for both indoor and outdoor use. The RealSense D435 is mainly used in applications such as augmented reality (AR), virtual reality (VR), robot navigation, object recognition, and autonomous driving.

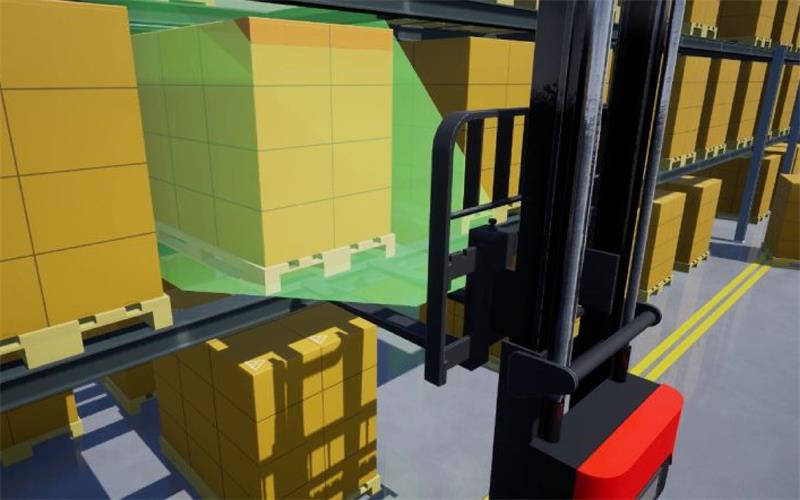

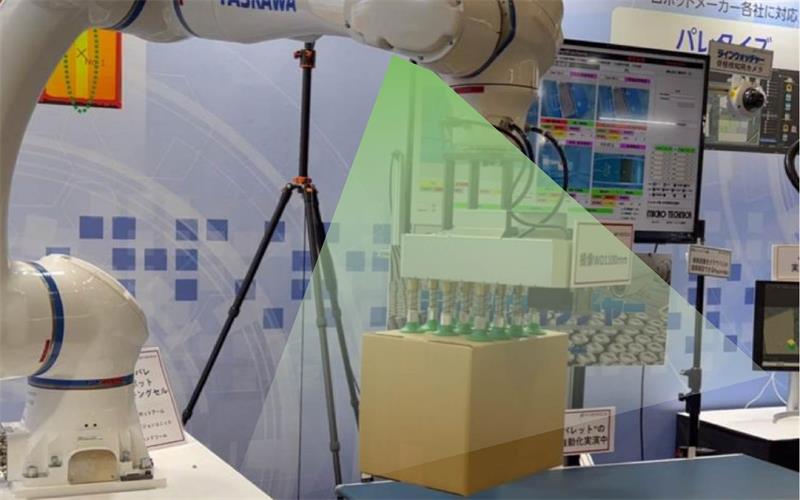

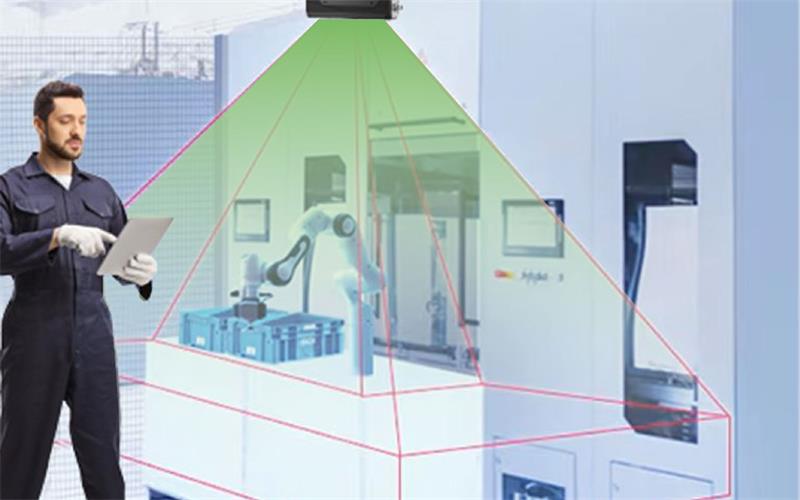

The DS86 is a model from the DS series cameras launched by Vzense. The DS series is an RGBD 3D camera based on Sony’s latest continuous wave Time of Flight(ToF) chip, the IMX570, and uses 940nm infrared light. It is compatible with both indoor and outdoor scenes. The Vzense DS series cameras are designed to industrial standards, offering high reliability, good data stability, high resolution, accuracy and precision, as well as strong outdoor light resistance. They feature bidirectional mounting holes for easy structural integration and fixing, an optional waterproof aviation plug design supporting IP67 high protection level, and customizable wide-angle lenses. The core application scenarios for the DS series 3D ToF cameras include AGV/AMR pallet recognition and obstacle avoidance, depalletizing and dynamic grasping and sorting, single-piece separation in logistics, warehouse location detection, graphical assistance in industrial automation, safety fences, fruit and vegetable recognition and picking in smart agriculture, and passenger flow statistics and behavior analysis.

Product parameter comparison

| Vzense DS86 | Realsense D435 | |

| Sensor | Sony DepthSense ToF CMOS | Intel® RealSenseTM Vision Processor D4 |

| Emitter laser | 940nm VCSEL x 2 | 850nm VCSEL |

| ToF/ Depth Resolution/ Frame rate | 640×480, Max.15fps | 1120×720, Max. 90fps |

| ToF HDR mode | Max.15fps | — |

| ToF FoV | 67°(H)x50°(V) | 87°(H)x58°(V) |

| RGB sensor specifications | 1600×1200,Global shutter, 71°(H)55°(V) | 1920×1080, Rolling Shutter, 69°(H)42°(V) |

| Output formats | 16bit (Depth) + 8bit (IR) + JPEG (RGB) | 16bit (Depth)+PNG(RGB) |

| Communication protocol | Ethernet(1000M) | USB3 |

| Physical interface | RJ45 | USB3 |

| Power supply and consumption | 12V~24V (DC),7W | 5V USB Type-C |

| Accuracy and precision error | <1% | <2% at 2 m |

| Detection distance range | 0.15m ~ 5m | 0.15m ~ 5m |

| Operating temperature | -20°C ~ +50°C | 0°C ~ +35°C, Max.44°C |

| Operating system and platform | Windows/Linux/Arm Linux/ROS | Linux \ Windows \ Mac OS \ Android \ Docker |

| Development language and wrapper support | C/C++/C#/Python | C/C++/C#/.NET /Python / LabVIEW, OpenCV, PCL, Unity, Matlab, OpenNI, UnrealEngine4 |

| Ingress protection | IP42/ IP67 | — |

| Certification | CE/ FCC/ FDA | FDA |

Based on parameter comparison, the D435 outperforms the DS86 in depth image resolution, frame rate, field of view, and support for operating systems and platforms, as well as wrapper support. The D435’s advantages in operating systems and wrapper support allow users more flexibility and creativity when using application solutions. However, its stringent requirements for operating temperatures, particularly in industrial production environments where many sites cannot meet the 0-35℃ requirement, and its difficulty in supporting applications with high data stability demands, are significant drawbacks.

On the other hand, the DS86 excels in accuracy, measurement distance, protection level, communication protocol, and operating temperature. Its advantages in operating temperature, protection level, and gigabit Ethernet data transmission stability make it widely applicable in harsh industrial environments, such as pallet recognition for automatic forklifts, depalletizing, workpiece identification and sorting in machining workshops, and other scenarios.

Product performance comparison

| Vzense DS86 | Realsense D435 | |

| Accuracy and precision | High | |

| Interference resistance | Strong | |

| Light resistance | Strong | |

| Power consumption | Low | |

| Resolution | High | |

| Ingress protection | High | |

| Wide-angle customization | Support | |

| Timeliness | High | |

| Algorithm complexity | Low | |

| Dection range | Large | |

| FoV | Large | |

| Operating system and platform | More | |

| Transmission stability | Strong |

Through performance comparison, it can be observed that the D435’s depth sensor’s wide field of view(FoV) is very suitable for applications such as robotics, augmented reality, and virtual reality, where it is crucial to expand the scene perspective as much as possible. The D435’s depth sensor also uses a global shutter, with a maximum frame rate of up to 90fps, which is more conducive to capturing fast-moving objects. On the other hand, the DS86’s ToF sensor measures quickly and accurately, being able to detect objects accurately in a short time. The 3D ToF technology maintains stable accuracy regardless of distance, allowing it to maintain high accuracy and precision even in long-range measurements. The time of flight technology also has strong interference resistance and is not affected by surface grayscale and features, nor by humidity, pressure, and temperature, which means it can maintain better performance in various environments. The ToF camera has strong ambient light adaptability, it uses an active infrared light source, can work normally in low light or no light conditions, and has strong light resistance, making it suitable for both indoor and outdoor use.

Comparison test data

This article selected multiple scenarios to test the Realsense D435 and Vzense DS86 cameras, including indoor and outdoor environments. The indoor environment tested a close-range white sculpture, black box, black pallet and blue pallet, and the outdoor environment tested a blue plastic bucket (with a white label). These scenes are quite representative and cover common situations for 3D cameras.

White plaster statue

Ambient light: Indoor light, about 200lux.

Distance from camera: 0.5m.

Testing target: As shown in the figure below:

Image comparison: Realsense D435 vs. Vzense DS86

| Realsense D435 | Vzense DS86 | |

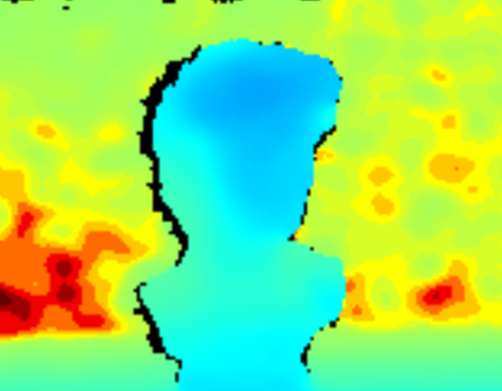

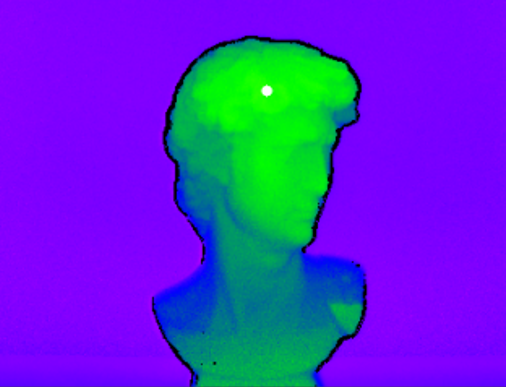

| Depth map |  |  |

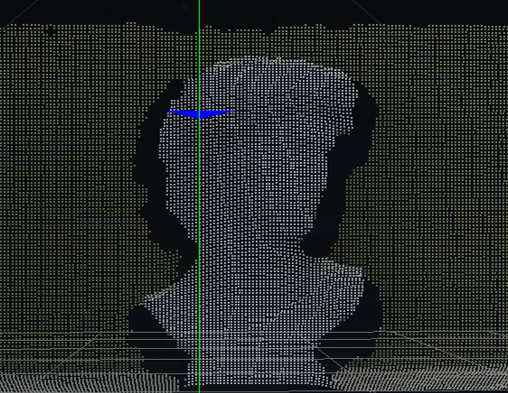

| Point Cloud map |  |  |

Test description:

On the contour edges of the white plaster statue, the D435 performs well in recognition, with a relatively clear separation from the background image. However, the depth information of the white plaster statue itself shows poor depth difference between pixels. To better present this effect, a color point cloud map was chosen for comparison, but the sculpture’s color point cloud image still appears quite blurred. In comparison, the DS86’s imaging, whether it is the separation between the white plaster statue and the background or the white plaster statue itself, is very clear. However, there is very obvious multipath interference in the corner between the desktop and the background board with the DS86, making the desktop look bent downwards.

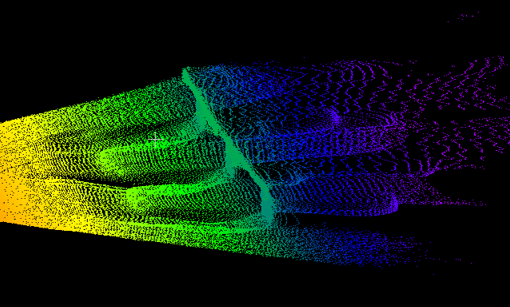

Black box

Ambient light: Indoor light, about 200lux.

Distance from camera: 0.5m.

Testing target: As shown in the figure below:

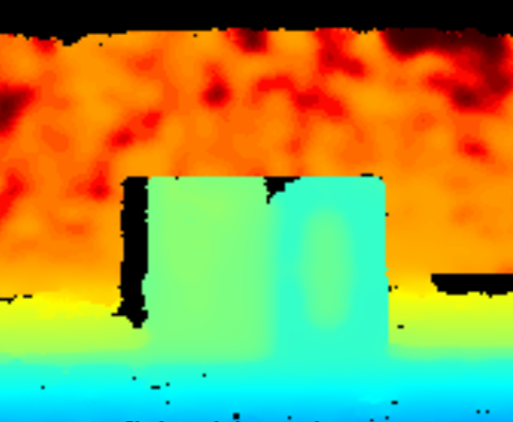

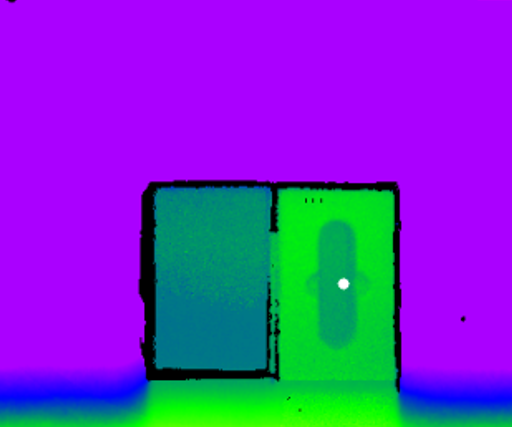

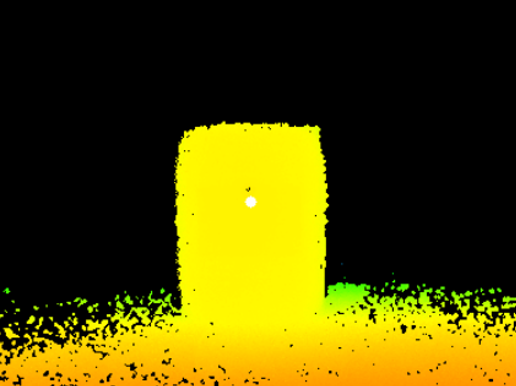

Image comparison: Realsense D435 vs. Vzense DS86

| Realsense D435 | Vzense DS86 | |

| Depth map |  |  |

| Forward point cloud map |  |  |

| Overhead point cloud map |  |  |

Test description:

In terms of performance on black objects, DS86 outperforms D435, especially when viewed from a top-down perspective of the point cloud images. The point cloud image of D435 exhibits significant distortion and deformation. In contrast, DS86 better represents the true shape of the black box, including a relatively complete representation of the recessed parts of the box, without noticeable multipath reflections. This is due to the low light refractive index of black objects, resulting in less prominent multipath reflections.

Despite the overall excellent imaging quality of DS86, it experiences larger fluctuations in the depth values of the box surface, manifesting as a thick appearance of the box surface in the top-down view. Conversely, the depth value variations on the box surface captured by DS435 are relatively smaller. Additionally, at the corners of the desktop, DS86 shows prominent multipath interference, with the desktop appearing concave and the sides of the desktop background panel slightly curved backwards.

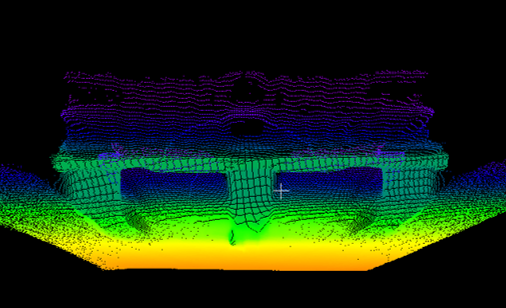

Blue pallet

Ambient light: Indoor light, about 200lux.

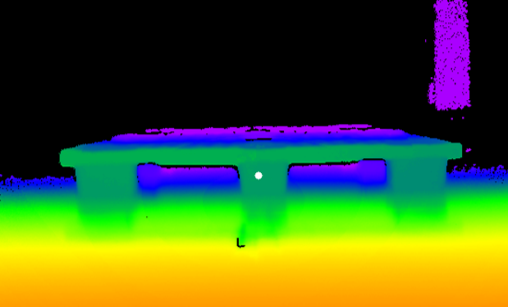

Distance from camera: 1.5m.

Testing target: Blue pallet. As shown in the figure below:

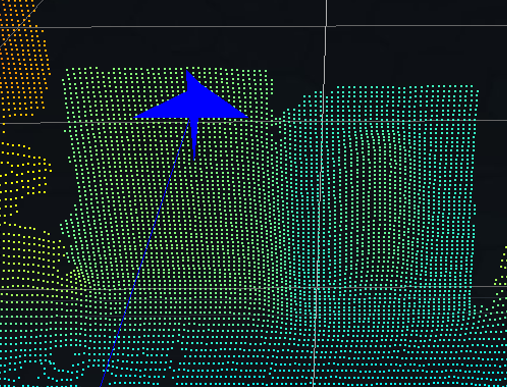

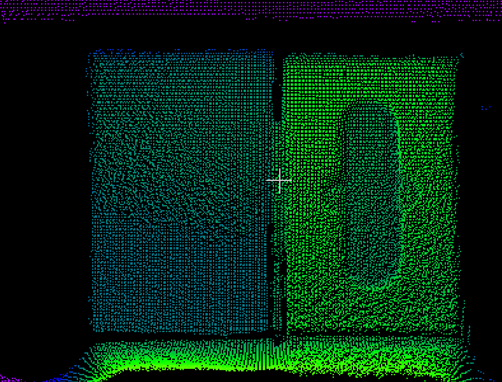

Image comparison: Realsense D435 vs. Vzense DS86

| Realsense D435 | Vzense DS86 | |

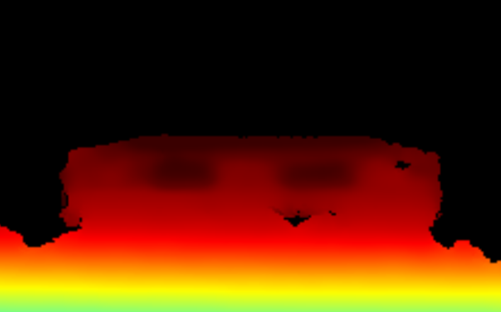

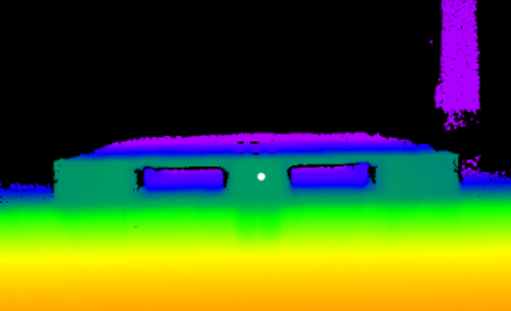

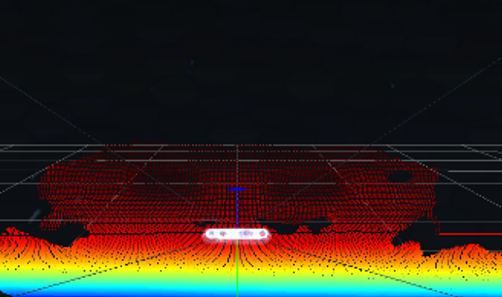

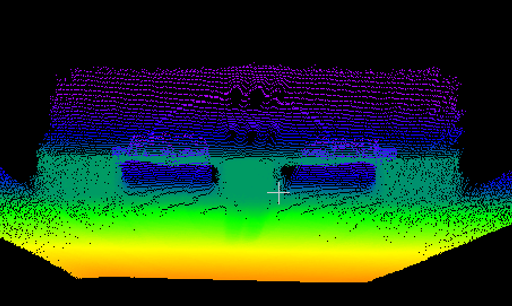

| Depth map |  |  |

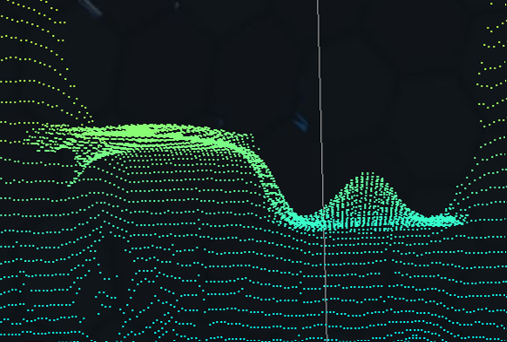

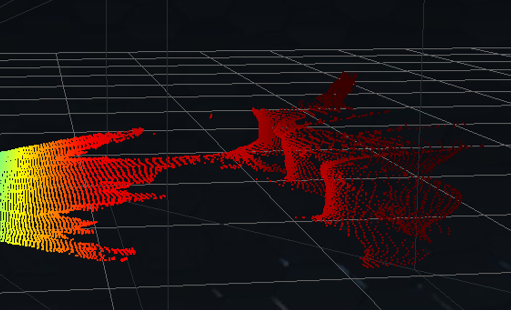

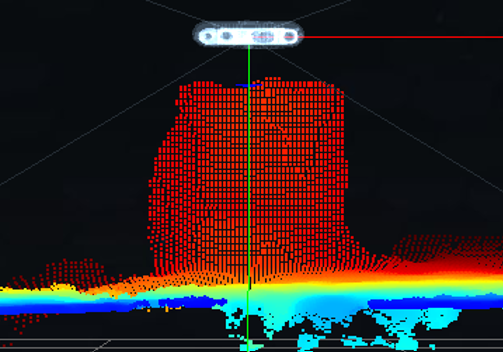

| Forward point cloud map |  |  |

| Lateral point cloud map |  |  |

Test description:

From the lateral point cloud map of the D435, it is evident that the pallet’s shape is severely distorted, making it difficult to use the depth map and point cloud image for pallet recognition. The DS86 can effectively display the characteristic information of the pallet, and the image quality is much higher than that of the D435. However, there is noticeable multipath interference in the ground in front of the pallet. This is because the surface of the blue plastic pallet is very smooth and highly reflective to light, and the ground is also very smooth with high reflectivity (as evidenced by the high brightness reflection observed in the test target images). This results in very noticeable multipath effects. Nevertheless, this multipath interference can be easily filtered out during pallet recognition, so it does not affect the recognition efficiency.

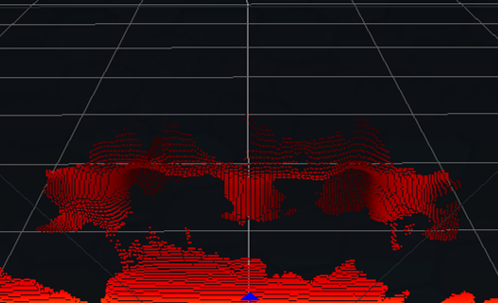

Black pallet

Ambient light: Indoor light, about 200lux.

Distance from camera: 1.5m.

Testing target: As shown in the figure below:

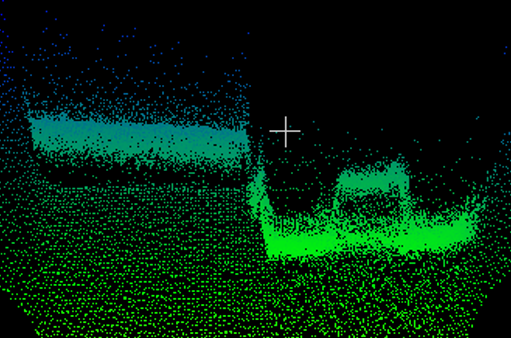

Image comparison: Realsense D435 vs. Vzense DS86

| Realsense D435 | Vzense DS86 | |

| Depth map |  |  |

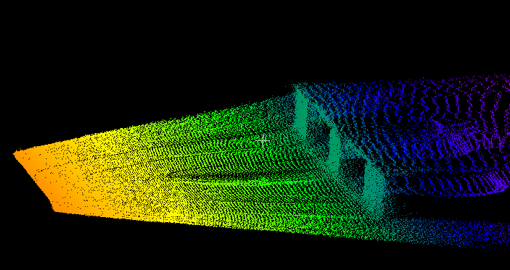

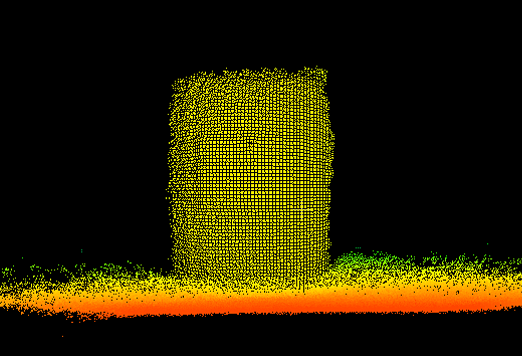

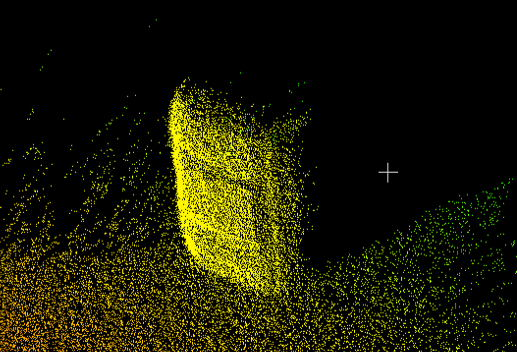

| Forward point cloud map |  |  |

| Lateral point cloud map |  |  |

Test description:

From the depth map and forward point cloud map, the D435 performs slightly better with the black pallet compared to the blue pallet. However, the lateral point cloud map shows that the black pallet’s shape distortion is still very severe, making the image quality inadequate for pallet recognition. On the other hand, the DS86 can still effectively display the characteristic information of the pallet, with image quality far surpassing that of the D435. Compared to the blue pallet test, the multipath interference on the ground in front of the black pallet is significantly reduced, which is related to the low reflectivity of the black pallet.

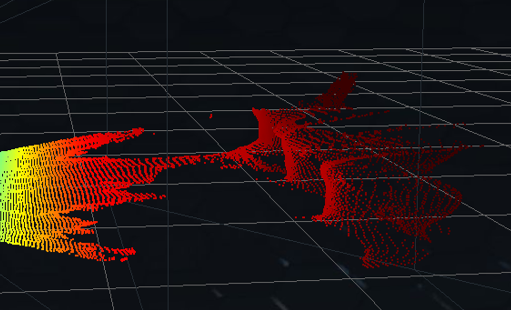

Blue plastic bucket

Ambient light: Outdoor light, about 87000lux.

Distance from camera: 1.5m.

Testing target: As shown in the figure below:

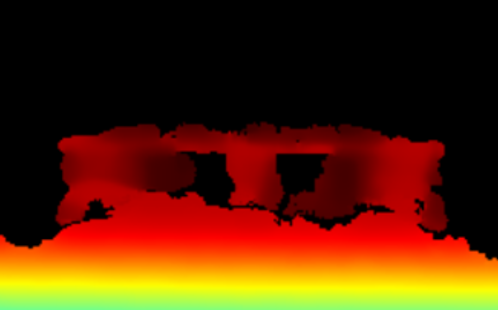

Image comparison: Realsense D435 vs. Vzense DS86

| Realsense D435 | Vzense DS86 | |

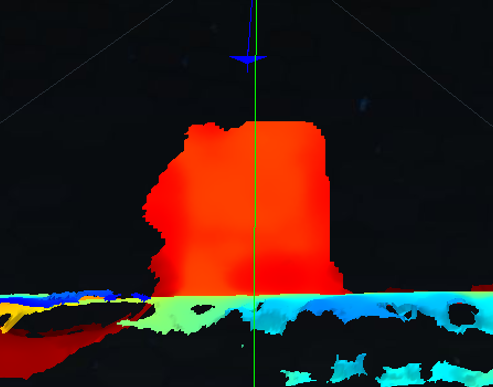

| Depth map |  |  |

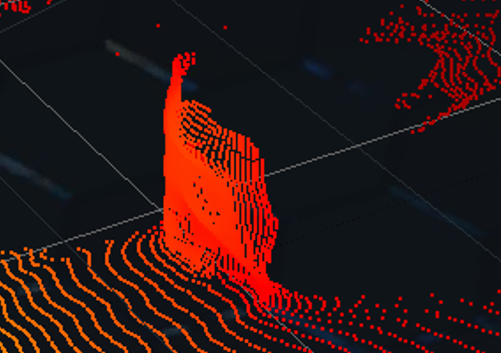

| Forward point cloud map |  |  |

| Lateral point cloud map |  |  |

Test description:

From the depth map and forward point cloud map of the D435, it is evident that the background information significantly affects the depth values of the blue plastic bucket, especially near the ground, where the shading from trees and the bucket’s shadow make it difficult for the D435 to find feature points. Additionally, from the lateral point cloud map, it can be seen that the surface depth quality of the plastic bucket is poor, with large fluctuations in depth values, failing to accurately reflect the true surface information of the plastic bucket.

The DS86’s depth map, in terms of both point cloud density and quality, is superior to the D435 and is basically unaffected by ambient light. However, on the surface of the plastic bucket, there is a significant difference in light reflectivity between the white label paper and the blue bucket, causing the relative difference in depth values of the label paper and the bucket surface to be greater than in reality.

Summary

In comparison, the D435 is compact and delicate in design with lower power consumption, while the DS86 is larger in size and consumes more power. This makes the D435 more user-friendly for integration with other devices. Under the test conditions mentioned, the 3D image quality performance of the Vzense DS86 ToF camera surpasses that of the Intel Realsense D435.

With the development of technology, 3D ToF camera technology has improved significantly and now outperforms stereo vision camera technology. However, the tests also highlighted the multipath interference drawbacks of ToF technology. If the object under test has pronounced concave shapes or corners, the ToF sensor may distort the measurement results due to multipath interference, with higher reflectivity of the object exacerbating this issue. Additionally, if there is a significant difference in light reflectivity between different surfaces of the object, the relative error in the depth values measured by the DS86 can increase. In practical applications, if this error affects target recognition and judgment, it needs to be corrected through compensation algorithms.

Furthermore, the principles of ToF technology make it unsuitable for environments with strong infrared light interference. For example, in special scenarios with high-temperature objects such as casting and forging industrial production sites, the high infrared light emission from molten iron or forged steel billets interferes too much with the 3D time of flight camera, preventing normal imaging, stereo cameras might be more suitable. Compared to stereo vision technology, the cost of ToF is relatively high, limiting its application in some scenarios. However, as the industry chain continues to develop, the cost of ToF camera technology is gradually decreasing.

In summary, the D435 has more advantages in consumer market fields such as virtual reality, augmented reality, and robotics. In contrast, the DS86 is better suited for more demanding industrial fields and can be widely used in scenarios such as pallet recognition and obstacle avoidance, depalletizing, dynamic grabbing, and sorting. Users can choose the product based on the required scenario.