Due to the principles and characteristics of time of flight technology, the following points shall be noted when installing and using ToF cameras:

Table of Contents

Avoid blocking optical path

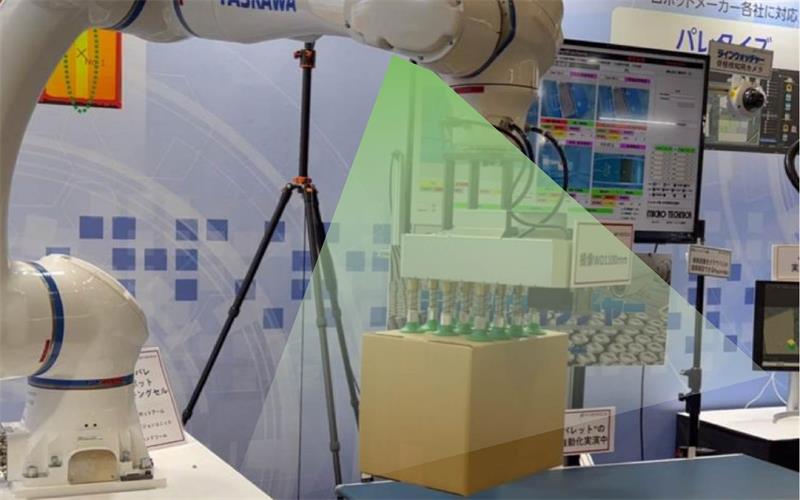

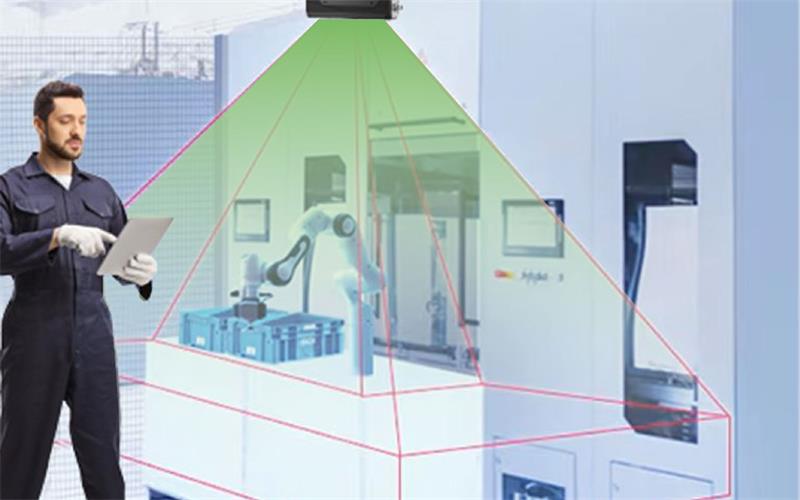

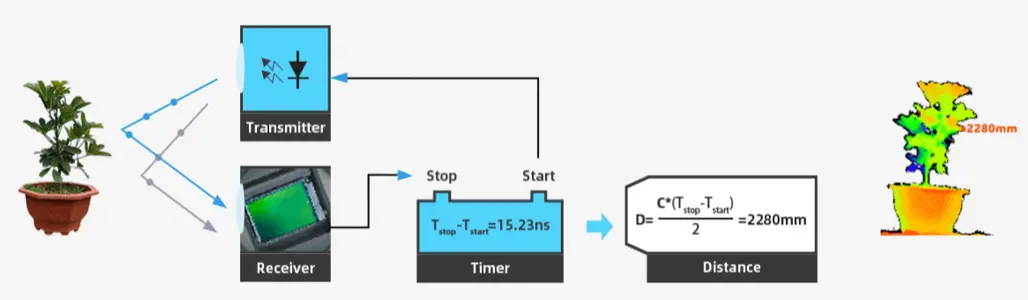

ToF technology measures distance by emitting laser light to the target object and returning to the sensor, as shown in below figure:

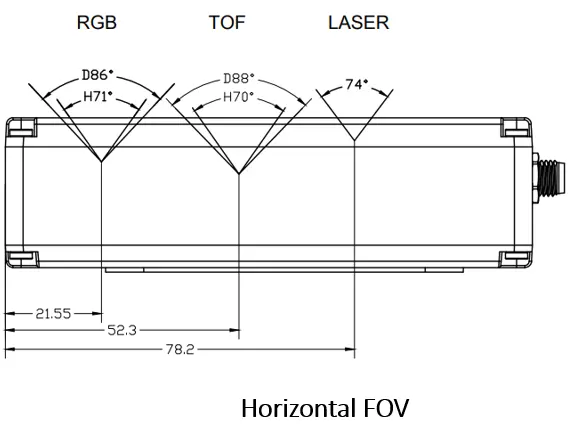

The laser is used for emitting light and the ToF lens is used for receiving light, each have its own field of view (FoV). The following diagram shows the field of view for a specific product, NYX650:

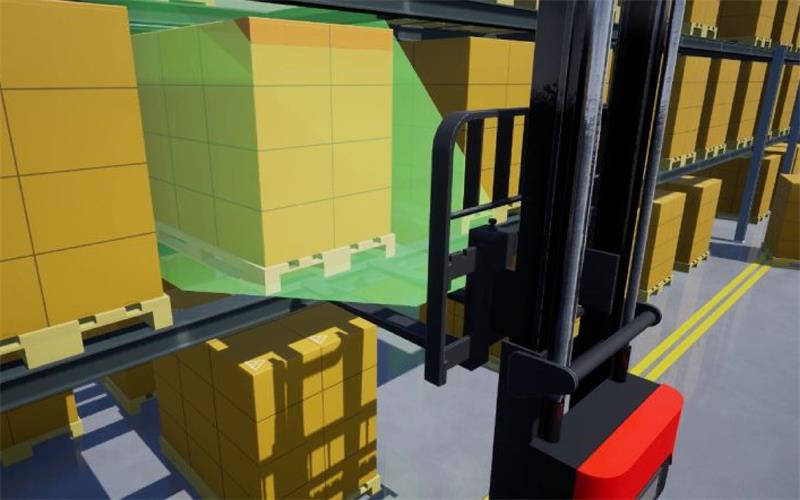

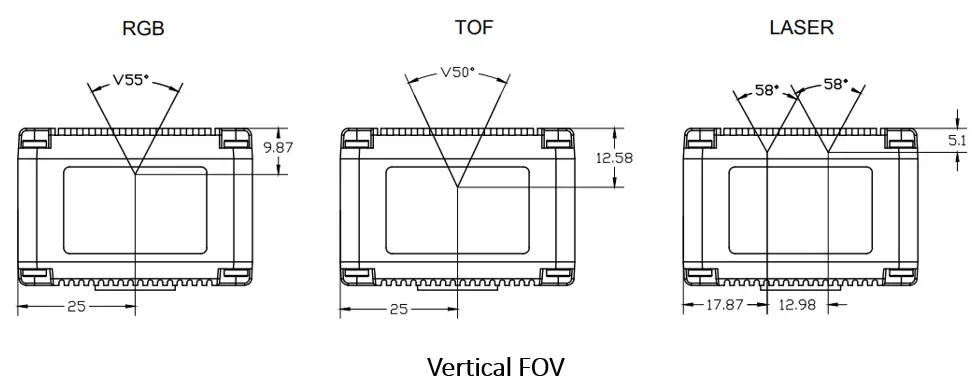

When installing a ToF camera, ensure that the camera’s field of view (including both the laser and lens fields of view) is not obstructed, otherwise this will result in invalid data measurement. The following diagram shows common incorrect installation ways:

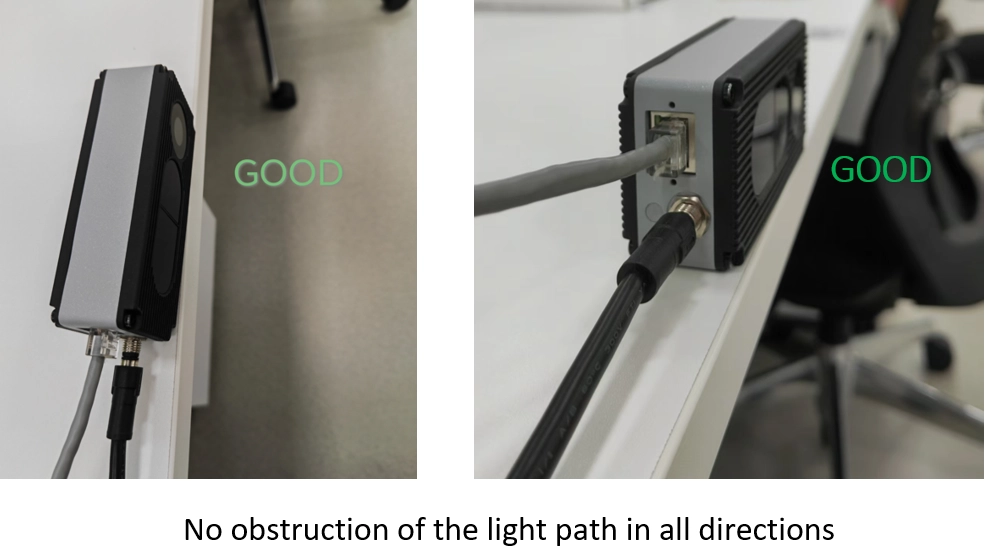

The correct installation method should be:

Avoid near object

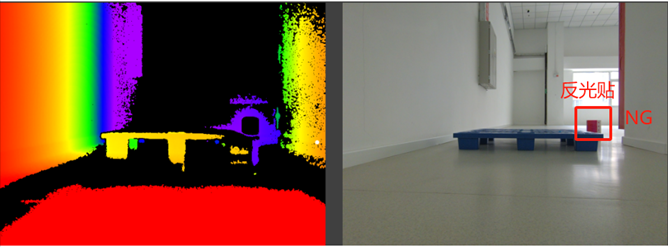

When installing a ToF camera, avoid surrounding with near objects, as they can cause strong reflective energy, leading to stray light phenomenon. As shown in the diagram below, when a near object (hand) is present, many depth data points on the black pallet become invalid. This phenomenon occurs without any changes to the camera configuration. The stray light caused by the nearby object (hand) results in significant data deviation on the black pallet, making the depth data incorrect.

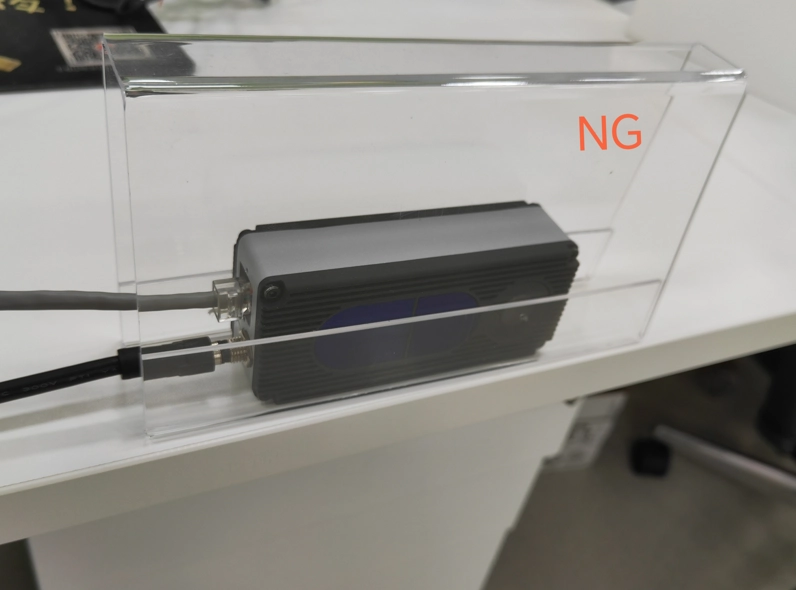

Avoid attaching a cover plate on the surface of the camera

Due to the principles of the ToF camera, it is prohibited to add any cover plate (such as glass, PMMA, etc.) to the surface of the ToF camera, as this will result in inaccurate test data. The following diagram shows an incorrect example:

Avoid fully enclosing the ToF camera

Some users use cameras in an scene with a lot of dust or other pollutants, and the customer installs a protective cover by himself, as shown in the picture. With this installation method, the fully enclosed environment will affect the normal heat dissipation of the camera. For environments with a lot of dust, you can choose products with a protection level of IP67. If it is indeed necessary to add a protective cover, ensure that the cover is made of metal and is in close contact with the ToF camera’s housing using thermal conductive silicone. Additionally, it is important not to place any material covers in front of the camera.

Avoid high gloss reflective film or same object

The high gloss reflective film or same object can cause significant stray light phenomenon, in below figure, the red high reflective film affects the depth data of the pallet.